YESWELDER BRAND POWER

As a rapidly emerging welding brand, YesWelder has a huge following. With the support and love of our fans, YesWelder has achieved two world firsts: the first-ever crowdfunding project for a welding machine, and the largest crowdfunding amount ever raised for a welding machine to date.

YesWelder has a solid brand foundation and a massive fan base, and is continuously growing.

Join us, and rapidly kick start your sales.

Views

WHAT WE SUPPORT

Trial Sales

Control

& Support

Support

Trial Sales

3-Months Free Trial Sales

YesWelder provides a three-month free trial sale support to help distributors test the market.

Distributors select the products they want to sell in stores and pay for the display samples.

If sales are generated, products will be sent to customers from YesWelder’s warehouse directly.

YesWelder settle with distributors at wholesale price, and the profit generated during the sales belongs to distributors.

When the free trial sale is going to expire, distributors can decide whether to go on with the sales ,and place order to YesWelder according to the actual situation. (NOTE: This support is valid only for the US market)

Control

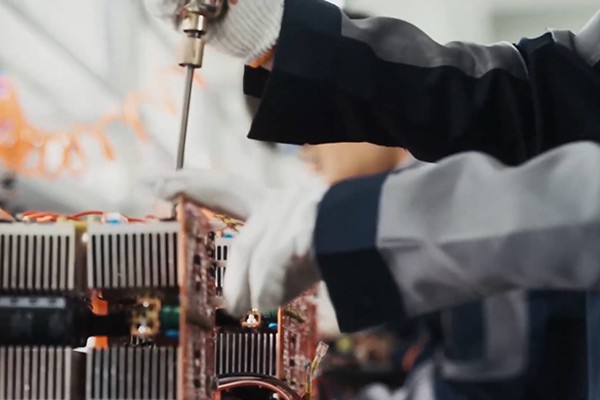

Advanced Quality Control

Seventeen years of manufacturing and brand-operation experience enable us to understand the market’s real needs, and the pain points for the products.

- Through creative innovation and advanced technology, we can always improve the user experience timely.

- We promise to use stable & high-quality components to ensure product durability.

- Every YesWelder product goes through a complete quality control inspection before packing.

& Support

Sales Promotion & Support

To help distributors to expand the market, YesWelder will invest in advertisement promotion, including but not limited to search engines like Google, forums, groups, and video advertising, which can increase brand exposure, establish brand images and make business happen easier.

Every distributor will be issued a sales target accomplishment award when they reach the annual sales target as encouragement.

Support

Reliable Aftermarket Support

To guarantee distributors’ rights, YesWelder has purchased product liability insurance for all YesWelder products, and a professional team of lawyers are avialable to provide legal assistance. Don’t worry about the quality problems if they do occur, YesWelder is your strong backing to solve your worries behind.

- Besides, in order to guarantee distributors’ interest and increase the market competitiveness, YesWelder provides strong after-sales service.

- 1% spare parts will be provided for quick after-service maintenance along with a one-year whole machine quality assurance.

- During the one-year warranty period, if the machine has malfunctions due to quality problems and can’t be repaired, customers are allowed to return the products to distributors for money or change a new model.

YesWelder will cover the refund, and distributors can cut from the purchase payment.

Some of our retailer partners

and platforms

Blogs About Welder

Learn the common knowledge of welding machines and the newest trends in welding from our blog.

Renting vs. Buying Welding Equipment for Your Projects

Choosing between renting and buying welding equipment is a critical decision that can significantly impact project efficiency and budget. Many professionals struggle with determining the best approach for their needs, often weighing the pros and cons without a clear direction. For short-term or infrequent projects, renting might seem ideal, offering flexibility and cost control. On the other hand, buying can be a wise investment for long-term use, ensuring access to equipment whenever needed. By understanding the specific requirements of your welding projects, you can make an informed decision that optimizes both performance and financial resources. Determining the Type of Welding When choosing welding equipment, understanding the type of welding required

Underwater Welding Explained & Industry Insights

Underwater welding presents unique challenges due to the harsh and unpredictable underwater environment. Water pressure, temperature fluctuations, and limited visibility make this task highly complex and risky. However, it is essential for maintaining and repairing marine structures, pipelines, and ships. To address these challenges, underwater welding has evolved with specialized techniques and equipment, ensuring divers can perform tasks safely and efficiently. These advancements have enabled professionals to work in challenging conditions, providing crucial solutions for the maritime and offshore industries. What Is Underwater Welding? Underwater welding is a specialized process that joins metal components while submerged in water. It is crucial for repairing and maintaining marine infrastructure, such as ships,

Welding Efficiency 101: Tips for Increasing Output

In the welding industry, inefficiencies can lead to significant downtime, wasted materials, and increased operational costs. Welders often struggle with inconsistent weld quality, extended work hours, and the need for rework, all of which diminish productivity. To address these challenges, adopting strategies that enhance welding efficiency is crucial. Companies can significantly boost output by optimizing techniques, improving welder skills, and ensuring proper equipment maintenance while maintaining high-quality standards. These practical steps reduce costs and enhance overall workflow, leading to a more efficient and effective welding process. Implementing these methods will ultimately drive better results and improve the bottom line. Key Factors of Welding Efficiency Welding Technique The technique used in