Welding is one of the key parts of construction, manufacturing and repairing things. For instance; fixing a bicycle frame or joining steel for a skyscraper requires specific combinations. Anything that comes together needs to adhere to something called a welding joint; it differs depending on a variety of factors.

In this guide, we will be discussing everything about different types of cooling joints available so you can equip yourself with the right knowledge using very low and non-overload technical lexicon.

Now let’s get started!

What Is a Welding Joint?

A welding joint is the location where two or more metal parts are joined together using heat and sometimes filler material. The joint determines how the pieces are positioned and how stress is distributed across them once fused.

There are many ways to prepare a joint, depending on the material, thickness, purpose, and desired strength. Choosing the correct welding joint ensures the final product performs safely and efficiently.

Why Is the Welding Joint So Important?

Welding joints are particularly important because of the lightweight, high-strength, and energy-efficient structures that are now a necessity. Today’s welding projects must withstand automation, robotics, severe environments, and world safety regulations.

An improperly executed joint results in product failure and safety concerns alongside overspending. The use of smarter materials paired with automated welding tools has made strength and dependability in joint precision a requirement rather than a choice.

You may also wonder Different Types of Welding, just read this article.

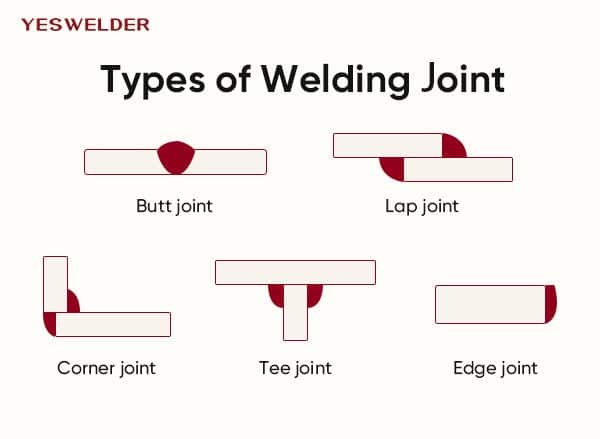

5 Basic Types of Welding Joints According to AWS

The American Welding Society (AWS) classifies all welding joints into 5 basic types, each serves a particular structural or functional purpose within a system. These fundamental joints are essential due to their versatility.

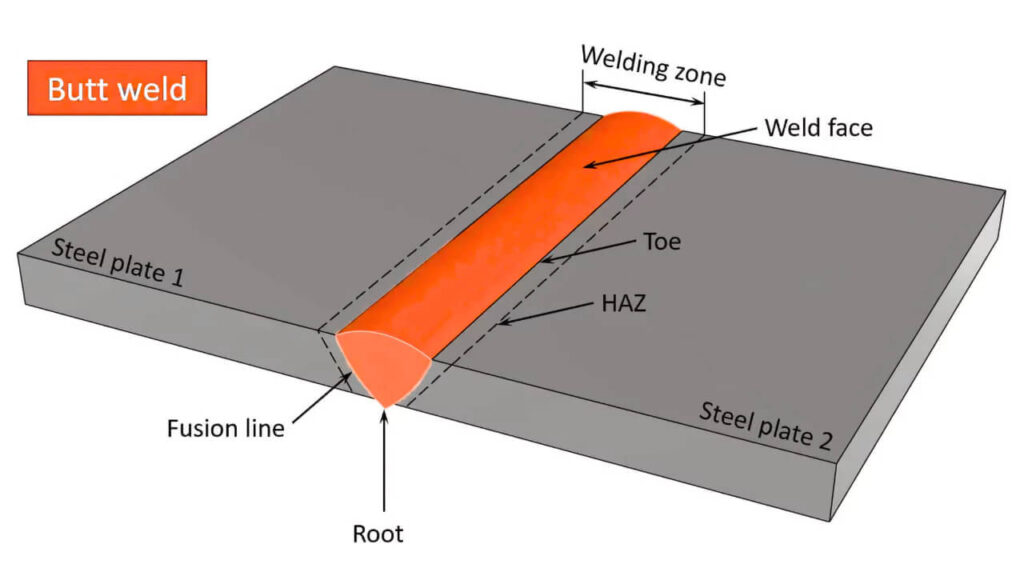

1. Butt Joint

The butt joint is perhaps the most common and simplest joint available today. Two adjoining pieces mounted parallel to each other can be welded at the edges, making it simple yet very reliable. Appropriate edge preparation on thicker components increases the strength of this configuration further.

Its variations, like V-grooves or U-grooves, add to permeability, thus enhancing how deeply they can penetrate, making it stronger overall.

Best For

This joint suits long, continuous work where deep, full penetration welds are required and thorough quality control inspections will occur. It is critical for certain applications where clean and powerful joins are indispensable.

Advantages

Butt joints can be examined with X-ray or ultrasonic testing, which makes these methods straightforward to evaluate. TIG, MIG, Stick welders, and even Submerged Arc Welding all can use and provide butt joints, so there is no shortage of processes that can put them to good use.

If the components are put into position with care and proper welding techniques are employed during stitching, the structures attain high strength and reliability.

Common Uses

- Oil and gas pipelines

- Bridge beams and structures

- Pressure vessels

- Aircraft and shipbuilding

- Heavy Structural Steel Fabrication

Pro Tip:

Adding backing bars or root passes supports better fusion while thick material welding. Always confirm full penetration on load-bearing structures checking roots.

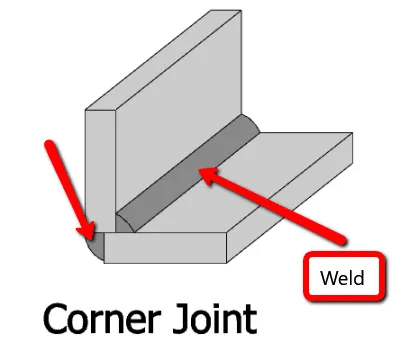

2. Corner Joint

A corner joint is formed when two metal pieces intersect at a right angle (90 degrees), creating an “L” shape. It is often utilised in the manufacturing of boxes, cabinets, or other closed enclosures where sides need to be sealed off completely.

There are two setups for this type of joint: open and closed (flush) corners, depending on the requirements for a particular case scenario.

Best For

It serves best as a frame for bounding thin to medium sheet metal surfaces as well as forming corners of metal enclosures or frames.

Benefits

Corner joints enable quick spot or MIG welders and have flexible position options. TIG welding is the preferred method when a clean, polished finish is required. Reinforcement can also be added for better load-bearing capacity.

Common Uses

- HVAC systems

- Electrical panels

- Metal cabinets

- Furniture frames

- Light-duty fabrication

Pro Tip:

With fillet welds, ensure that the throat size is sufficient for anticipated load stress. While neat appearances are what small fillet welds can provide, they are prone to failure under stress.

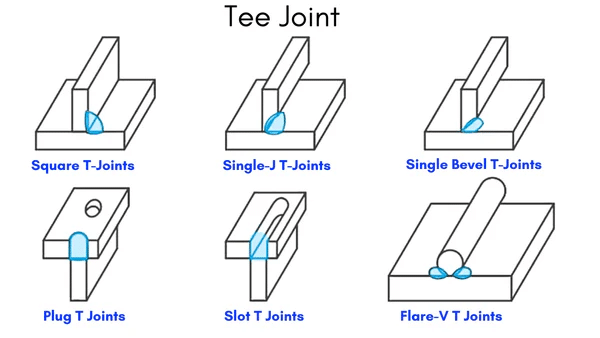

3. T-Joint

T-joints are created when one metal piece is inserted vertically into another, resembling the letter “T”. The vertical and horizontal loads acting on this joint make weld strength and fusion critical considerations.

Best For

T-joints are ideal for use in structural framing as well as in cross-support applications. They are useful in areas where multiple components intersect and need to be merged securely with minimal movement.

Advantages

The allowance of double-sided welding increases adaptability for these joints, making them compatible with all major welding processes, including robotic automation; groove or fillet welds can be employed for additional strength, making these joints unyielding.

Common Uses

- Heavy equipment frames

- Metal structures and supports

- Automotive chassis and railings

- Agricultural and construction machinery

- Trailer and container fabrication

Professional Advice:

If exposed outdoors, better protection comes from sealing lap joints with paint or powder coat that’s resistant to corrosion after welding. This protects against moisture between plates.

4. Lap Joint

Lap joints increase surface area contact by overlapping two metal sheets that are welded along the perimeter of the joint’s overlap edge. This joint is most suitable for thin sheets where edge welding would not work.

Best For

Lap joints are ideal for attaching thin materials and in scenarios where shear strength is preferred over tensile strength. They are also good for differing thicknesses.

Advantages

Due to their simple setup, lap joints can be easily welded, which makes them useful in quick manufacture systems. In addition to better shear force resistance, they can be welded unilaterally or bilaterally for additional strength. Thus, depending on finishing requirements, TIG and MIG processes can be used.

Common Uses

- Automotive panels and bodyworks

- HVAC duct systems

- Sheet metal frames

- Stainless steel furniture and appliances

- Light enclosures and structural skins

Pro Tip:

Use clamps or tack welds at critical locations before full welding to maintain placement between pieces. This is best for keeping angles sharp and preventing warping.

5. Edge Joint

Edge joints result when two plates are set parallel to each other with their edges matched and aligned, forming a given angle, then welded at that edge. Its use is mostly with sheet metal in low-load applications or during sealing functions.

Best For

Ideal for enclosures, tanks, and containers, as these structures shield welds meant to seal with minimal weight-bearing loads. These apply best for thin materials constrained by limited structure.

Advantages

Offers a clean, low-profile weld further enhancing airtight seals which may boast aesthetics. Better control or precision through seam welding makes these prefer TIG welding machines.

Common Uses

- Fuel and water tanks

- Box containers made out of sheet metal

- Exhaust ducts and chimneys

- Custom steel enclosures

Pro Tip:

Edge joints make cosmetic finishes easy, as well as creating watertight seals. For increased strength, use additional reinforcements like backing bars or stiffeners.

Comparison Table Between 5 Basic Types of Welding Joints

| Joint Type | Strength | Common Uses | Best For | Limitation |

| Butt | High (with full penetration) | Pipes, frames | Strong, flush joints | Edge alignment crucial |

| Tee | Moderate-High | Structural supports | Easy layout | Prone to stress cracking |

| Lap | Moderate | Sheet metal, cars | Quick, thin sheets | Traps moisture |

| Corner | Moderate | Frames, enclosures | Clean finish | Needs reinforcement |

| Edge | Low-Moderate | Boxes, tanks | Thin metal sheets | Not for high load |

How to Choose the Correct Joint

Choosing a suitable welding joint will depend on:

- Material thickness

- Welding position (flat, vertical, overhead)

- Expected load/stress on component

- Ease of reach and alignment

- Aesthetic exposure or needs

- Time and cost for prep work

As is evident from the last two lines of this section, there’s considerable variance from project to plaid answer—each project in a set offers different requirements. Still, with this guide, you are adequately equipped to make smart decisions.

What is the strongest welding joint?

Properly performed groove weld butt joints are widely regarded as the strongest joints available due to their full penetration capabilities.

Can different types of joints be combined?

Sure, hybrid designs do combine styles aimed at making them stronger or easier to weld complex pieces.

Which joint is best for beginners?

Fillet weld lap joints are forgiving and thus very easy to learn for newer welders so they can build confidence quickly after starting.

Do welding joints impact corrosion resistance?

Not if done correctly! Poor design ruins everything—exposed edges tend to get moisture trapped inside, leading to them corroding slowly over time, so proper technique in creation alongside protective finishes is needed for separating exposed edges.

Are robotic welders replacing human welders in joint making?

Robots handle repetitive tasks better than humans, so they are taking some work off skilled operators, but complex seams still need experts involved, which means, alongside human supplementing, they still require quite an advanced arsenal.

Final Thoughts

Even though welding joints may appear elementary, they are the building blocks behind every welded construction. With emerging industries and new technologies in 2025, recognising different kinds of welds and their applications becomes imperative.

Whether you are a professional welder, hobbyist, or simply interested in knowing how different welding machines and structures are made out of metal pieces, a thorough guide provided above explaining all essential welding joints has clarified everything.