Aluminum is everywhere, from aircraft and boats to bicycles and architectural frames. It’s light, strong, and corrosion-resistant, making it a favorite for industries that demand performance without extra weight. But when it comes to joining two aluminum pieces together, even experienced welders pause for a moment.

Why? Because aluminum behaves differently from steel. It melts at a lower temperature, forms an oxide layer that resists bonding, and conducts heat so well that managing the weld pool becomes tricky.

So, can you weld aluminum to aluminum effectively and get a clean, strong joint? The answer is yes, but it requires the right tools, techniques, and understanding of the material’s behavior.

This guide walks you through the process of welding aluminum, the best methods to use, and professional tips to ensure strong, clean welds that last.

Understanding Aluminum’s Nature

Before jumping into the welding process, it’s essential to understand what makes aluminum different.

1. High Thermal Conductivity

Aluminum dissipates heat rapidly, which means the heat you apply spreads out quickly. This makes it harder to maintain a stable weld puddle and often requires more heat than you’d expect. Welding equipment suppliers recommend using a TIG welder to control heat better.

2. Oxide Layer

Aluminum forms a tough oxide layer when exposed to air. This oxide melts at around 3,700°F, while the aluminum beneath it melts at only 1,200°F. Unless removed, this layer prevents proper fusion. Professional welding helmet protection is essential to avoid UV damage during this phase.

3. Soft and Sensitive

Aluminum is softer than steel, making it more prone to warping or distortion under excessive heat. It also absorbs impurities easily, leading to porosity if cleanliness isn’t maintained.

Standard Methods to Weld Aluminum

Aluminum can be welded using several techniques. The correct method depends on the thickness, type of joint, and application.

1. TIG Welding (GTAW)

TIG (Tungsten Inert Gas) welding is the gold standard for welding aluminum when you need precision and control. It produces clean, strong welds with minimal spatter.

Why It Works Well:

- Uses a non-consumable tungsten electrode.

- Provides precise heat control.

- Ideal for thin sheets and detailed work.

Best Shielding Gas:

Pure Argon or an Argon-Helium mix helps stabilize the arc and protect the weld pool.

Tip: Always use AC (Alternating Current) for TIG welding aluminum because it helps remove the oxide layer during the process.

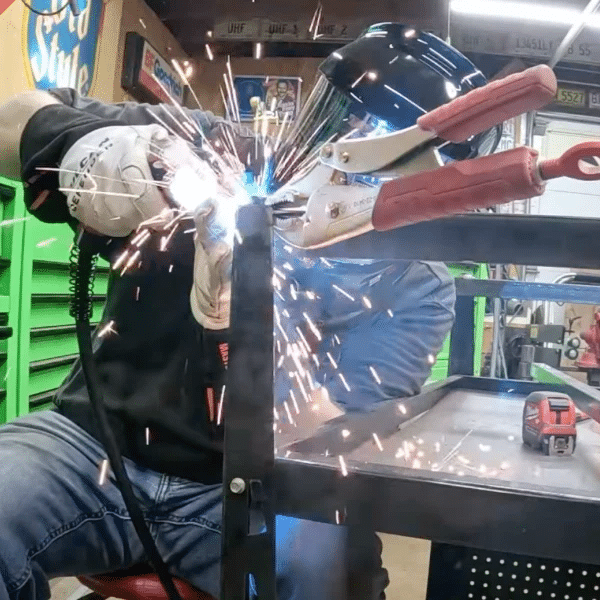

2. MIG Welding (GMAW)

Mig welder is faster and easier to learn compared to TIG. It’s preferred for thicker aluminum sections or when productivity is a priority.

Why It’s Effective:

- Continuous wire feed allows consistent welds.

- Works great on thicker materials.

- Easier for long joints.

Key Setup Requirements:

- Use 100% Argon as the shielding gas.

- A spool gun or push-pull gun prevents wire-feeding issues since aluminum wire is soft and can kink.

Pro Tip: Clean your base metal thoroughly. Even minor oil or oxide buildup can cause porosity and weak welds.

3. Laser Welding

Laser welding is used in advanced manufacturing applications where precision is critical. It delivers deep penetration with minimal distortion.

Benefits:

- Very clean and fast.

- Suitable for automation.

- Great for thin aluminum components.

However, laser systems are expensive and require controlled conditions, making them more suitable for industrial production rather than workshops.

4. Friction Stir Welding (FSW)

This is a solid-state welding technique, meaning the metal doesn’t melt during the process. Instead, a rotating tool stirs the joint edges together at high speed, fusing them through frictional heat.

Advantages:

- No filler metal required.

- Produces high-strength, defect-free welds.

- Excellent for aerospace, rail, and shipbuilding applications.

FSW works best for thick, flat panels where mechanical strength and surface finish are critical.

Preparation

Whether you’re TIG welding a bike frame or MIG welding an aluminum gate, preparation determines the quality of your weld.

1. Clean Thoroughly

Use a stainless steel wire brush or a dedicated aluminum brush to remove oxides. Wipe the surface with acetone to eliminate grease or contaminants. Never use a brush that’s been used on steel; it will contaminate the aluminum.

2. Preheat When Necessary

Preheating aluminum to 200–300°F helps prevent cracking and ensures uniform heat distribution, especially on thicker materials.

3. Fit-Up and Clamping

Ensure tight joints with proper alignment. Aluminum expands under heat, so use clamps or fixtures to keep parts in position.

4. Choose the Right Filler Material

Common filler rods include:

- ER4043: Good for general-purpose welding and easier to work with.

- ER5356: Provides stronger welds and better color match for anodized aluminum.

Always match filler alloy with your base material for optimal results.

Shielding Gas Selection

The shielding gas you choose directly impacts weld quality and appearance.

- Pure Argon: Best for most TIG and MIG applications. Produces smooth, shiny welds with minimal spatter.

- Argon-Helium Mix: Ideal for thicker aluminum because helium adds heat for deeper penetration.

Avoid reactive gases like CO₂ or hydrogen, they cause contamination and porosity in aluminum welds.

Controlling Heat and Distortion

Aluminum’s high thermal conductivity makes heat management crucial. Too much heat leads to warping; too little causes poor fusion.

Tips for Managing Heat:

- Use short weld passes instead of long continuous beads.

- Alternate between opposite sides of the joint to distribute heat evenly.

- Allow cooling time between passes.

- Use heat sinks or backing bars to absorb excess heat.

Dealing with Common Welding Issues

Even skilled welders encounter challenges with aluminum. Here’s how to troubleshoot them:

1. Porosity (Tiny Holes in Weld)

Cause: Contaminants, moisture, or improper gas coverage.

Fix: Clean the surface, increase gas flow slightly, and check for leaks in your torch or hoses.

2. Cracking

Cause: High thermal stress or incompatible filler metal.

Fix: Preheat thick sections, reduce amperage, and use proper filler.

3. Lack of Fusion

Cause: Low heat or poor joint prep.

Fix: Increase amperage, improve fit-up, and ensure oxide removal.

4. Excessive Spatter or Burn-Through

Cause: Incorrect settings or poor travel speed.

Fix: Adjust the wire feed, voltage, and maintain consistent motion.

Finishing and Post-Weld Cleaning

After welding, you’ll notice a thin layer of aluminum oxide and discoloration near the bead.

- Use a stainless brush to clean the weld.

- If the piece will be anodized or painted, remove all oxidation to ensure adhesion.

- You can also lightly sand or polish the weld for a professional finish.

Safety First

Welding aluminum produces bright UV light and intense heat. Always wear the right protective gear:

- Auto-darkening welding helmet (set to shade 10–12).

- Flame-resistant gloves and jacket.

- Respirator or fume extraction (aluminum welding produces ozone and metal fumes).

- Fire-resistant workspace setup.

When to Choose Aluminum Welding Over Alternatives

Sometimes, welding isn’t the only option aluminum can also be joined by riveting, adhesive bonding, or mechanical fastening. But welding becomes the preferred choice when:

- You need a permanent, high-strength bond.

- The project demands leak-proof joints (like fuel tanks or pipelines).

- Weight reduction and aesthetics matter.

Welding aluminum demands patience, preparation, and precision. From TIG for delicate work to MIG for thicker sections and friction stir for advanced fabrication, several techniques can deliver clean, strong joints.

The secret lies in mastering heat control, keeping the surface spotless, and choosing the right filler and gas. Once you understand how aluminum behaves under heat, you can produce welds that are both structurally sound and visually impressive.

So yes, aluminum can absolutely be welded to aluminum, and when done right, the results are durable, lightweight, and built to last.

Related Reading

1.Can You Weld Aluminum to Steel?

Welding aluminum to steel is not a normal “just clamp and arc” job. Here’s what actually works and why most joints fail early.

2.Can You Weld Steel to Aluminium?

Steel and aluminium behave very differently under heat. Learn the risks, common workarounds, and when you should not attempt it.

3.Aluminum Welding Guide

From surface cleaning to heat control, this guide walks you through how to get strong, clean aluminum welds with fewer cracks.

4.MIG vs TIG Welding: Which Process Is Better for Your Job?

Learn when to use MIG for speed and when TIG is worth it for precision, especially on thinner or more sensitive metals.

5.Welding Cracks: Common Causes and How to Prevent Them

Cracking, brittleness, and early weld failure are common when joining dissimilar metals or overheating thin aluminum. Learn how to avoid it.

FAQs

1. Can you weld aluminum without a filler rod?

Yes, you can weld aluminum without a filler rod, especially when using a solid-state method like Friction Stir Welding. However, most traditional methods like TIG or MIG welding require a filler rod to ensure proper bonding and strength.

2. What is the best welding method for aluminum?

The best method depends on the project. TIG welding is ideal for precision work and thinner materials, while MIG welding is better for thicker sections and faster productivity. Laser welding is used in advanced manufacturing for precise joints in thin aluminum.

3. Do I need to preheat aluminum before welding?

Preheating aluminum is recommended for thicker materials (200-300°F). It helps reduce thermal stress, prevent cracking, and ensures better heat distribution during welding.

4. Why does aluminum welding produce porosity, and how can I prevent it?

Porosity occurs when contaminants or moisture are present on the surface. To prevent it, thoroughly clean the aluminum before welding, increase gas flow, and check your equipment for leaks.

5. How do I choose the right welding machine for aluminum?

When selecting a welding machine supplier, choose a machine capable of delivering precise heat control. For TIG welding, a machine with adjustable amperage is ideal, while MIG welding machines should support aluminum wire and offer good wire feed mechanisms.