A 110V welding machine lets you weld at home using a standard wall outlet—no shop rewiring, no electrician required.

For DIY repairs, auto body work, and light fabrication, it’s often the most practical choice if you pick the right one.

In this guide, we’ll break down what a 110V welder can realistically handle, which specs actually affect your weld quality, and where most buyers get disappointed. By the end, you’ll know exactly what to look for—and what to ignore—before spending your money.

What is a 110V welding machine?

A 110V welding machine runs on a standard household outlet and is designed for light-duty welding.

Most homes provide 110–120V power, which makes these welders easy to use without electrical upgrades. Because of that limitation, they focus on thinner materials, shorter welds, and portable projects rather than heavy fabrication.

What can a 110 welder realistically weld?

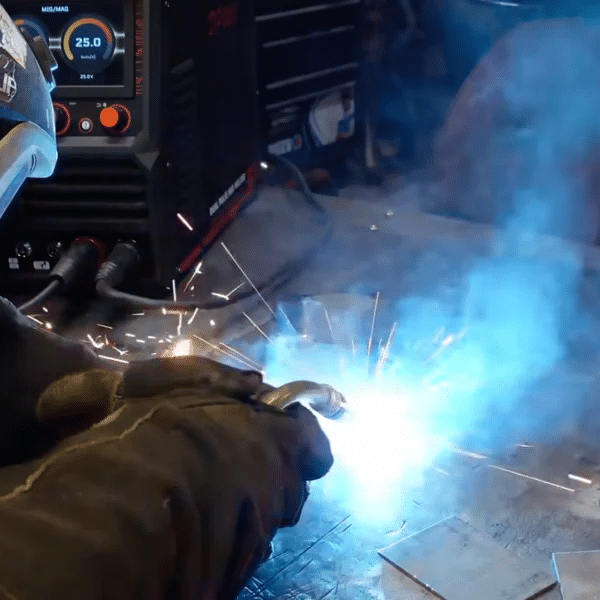

A 110V welder is best for thin steel and light repairs, usually up to 1/8 inch with proper joint prep.

In real home garages, performance is often limited by 15-amp household circuits, not the machine itself.

You’ll get the best results on:

- Sheet metal and patch panels

- Small brackets, tabs, and frames

- Auto body repairs

- Light farm, gate, or trailer fixes

Expect slower travel speed and shorter welds. Long, continuous beads will quickly push the duty cycle limit.

110V vs 220V: Which One Makes Sense for Home Use?

A 110V welding machine makes sense when convenience matters more than raw power.

For many home users, it avoids the cost and hassle of adding a 220V outlet.

Most people choose 110V because it:

- Plugs into standard household outlets

- Avoids breaker panel upgrades

- Weighs less and stores easily

- Works well in garages and small shops

If you weld a few times a month instead of every day, this tradeoff is usually worth it.

What Is the Best 110V Welder for Beginners?

There isn’t one “best” 110V welder for everyone. The right choice depends on process, project type, and budget.

Based on real-world home use, these categories come up most often:

Stick Welding (Performance-Focused)

Machines like Miller Electric Maxstar 161S appeal to users who want excellent arc stability and rod control. They suit experienced welders running common rods within 110V limits.

Stick Welding (Best Value for DIY)

The Hobart Welding Products Stickmate 160i is often chosen by homeowners who want dependable stick performance without premium pricing.

Budget Multi-Process (MIG / TIG / Stick)

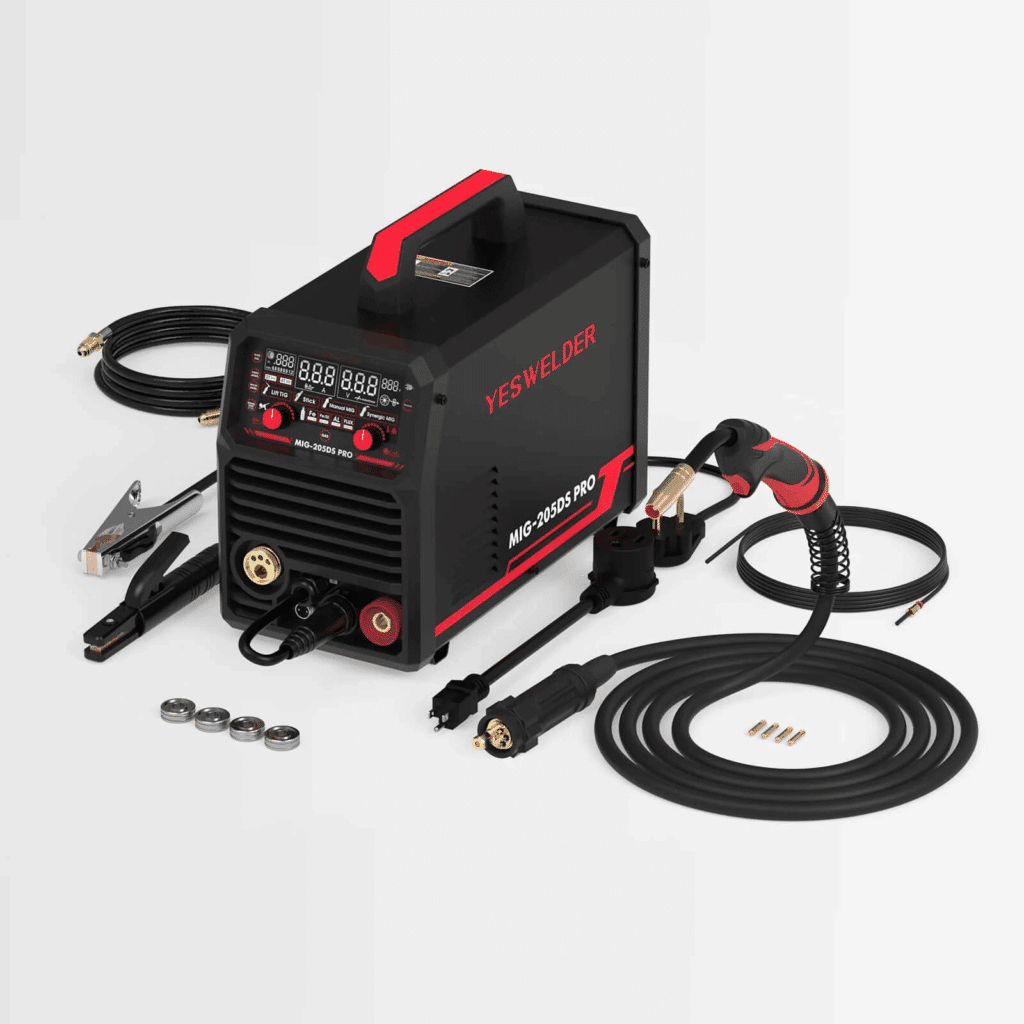

Multi-process inverter welders like the YesWelder Arc Pro 165A attract DIY users who want flexibility in one compact unit. Switching between a MIG welder, a stick welder, and a basic TIG welder saves space and money.

Entry-Level MIG / Flux-Core

Models such as the Lincoln Electric Easy MIG 140 and Hobart Handler 140 remain popular for thin steel, auto body work, and general repairs because they’re easy to learn and live with.

Beginner-Friendly Gasless Multi-Process Option

The YesWelder Flux-135 PRO is a good entry-level choice for beginners who want a simple, gasless setup on 110V power.

It supports flux-core MIG, lift TIG, and stick welding, with smart synergic control that helps new users dial in settings faster. This makes it a practical option for light repairs and garage projects without shielding gas.

Portable & Compact Options

Inverter-based welders from Eastwood and YesWelder work well if storage space is tight or portability matters.

Rather than chasing one specific model, match the welder to your main welding process, duty cycle needs, and material thickness.

Why Some Home Welders Choose YesWelder?

Many DIY welders choose YesWelder for its multi-process flexibility and compact inverter design at a reasonable price.

These machines fit light fabrication, auto body work, and home repairs where standard 110V power is the main constraint. As with any brand, the key is matching output and duty cycle to what you actually weld.

Key Features That Actually Matter on a 110V Welder

This is where most buying decisions should focus.

How Much Amperage Do You Really Need?

A solid 110V welder typically delivers 90–140 amps, which is enough for:

- Clean welds on thin sheet metal

- Light structural work near 1/8 inch

- Better arc stability at lower settings

Lower output limits penetration. Higher output increases versatility—even if you rarely max it out.

Why Duty Cycle Matters More Than Peak Amps

Duty cycle controls how long you can weld before overheating, and on 110V machines, it matters more than advertised max amperage.

- 20% @ 90A → 2 minutes welding, 8 minutes cooling

- 30% or higher → smoother workflow, less waiting

If you plan to stitch-weld or run beads longer than a few inches, aim higher.

Wire Size Compatibility

A good 110V welder supports:

- 0.023 in for thin sheet metal and auto work

- 0.030 in for general repairs

- 0.035 in only on higher-end 110V machines

Smaller wire gives better control and reduces burn-through.

Gas MIG vs Flux-Core Support

A versatile 110V welding machine supports both gas MIG and flux-core welding.

- Gas MIG works best indoors for clean welds

- Flux-core works better outdoors and on slightly thicker steel

Machines that support both offer more flexibility for home users.

Voltage Control

Adjustable or infinite voltage control improves arc stability and bead shape, especially on thin material.

Compared with simple two-setting machines, fine control reduces burn-through and spatter.

Safety Features to Look For

Important safety features include:

- Thermal overload protection

- Cooling fan

- Overcurrent protection

- Quality ground clamp

These features protect both the machine and the user during long-term use.

Who Should (and Shouldn’t) Buy a 110V Welder?

A 110V welder is a solid choice for:

- Beginners

- DIY users

- Light-duty welding work

It fits well in home garages, apartment workshops, and hobby setups where standard outlets are the only power option.

That said, a 110V welding machine is not designed for heavy or continuous work.

If you regularly weld thick steel, structural beams, or run long, uninterrupted welds, a 110V unit will feel limiting. In those cases, a 220V welder delivers better penetration, longer duty cycles, and more consistent performance.

Common Mistakes When Buying a 110V Welder

Most mistakes come from expecting more power than a 110V machine can deliver.

Common errors include:

- Ignoring duty cycle ratings

- Choosing machines with limited voltage control

- Using incorrect wire sizes

- Expecting deep penetration on thick metal

Understanding these limits prevents frustration.

How to Compare Different 110V Welding Machines

Compare 110V welding machines by:

- Maximum amperage

- Duty cycle

- Wire size compatibility

- MIG and flux-core support

- Warranty coverage and user reviews

This helps narrow down reliable options.

What accessories improve performance on a 110 welder?

The right accessories help you get cleaner welds from a 110V welding machine.

Helpful add-ons include:

- Auto-darkening helmet

- Quality ground clamp

- Proper shielding gas

- Clean wire liners

- Correct contact tips

Accessories improve results more than raw power.

Maintenance Tips for Long-Term Reliability

Good habits include:

- Keeping wire dry

- Replacing worn contact tips

- Cleaning liners regularly

- Checking cable connections

Basic maintenance keeps arc performance consistent and extends machine life.

Conclusion

A good 110V welding machine gives you clean, controlled welds without special power outlets. When used within its limits, it handles home repairs, light fabrication, and DIY projects with ease.

Focus on amperage range, duty cycle, voltage control, and wire compatibility. Match the machine to the work you actually do—not what you hope it can handle.

If you want help comparing specific 110V welding machines or choosing the right setup for your projects, tell me what you plan to weld, and I’ll guide you step by step.

FAQs

The most trusted brands for 110V welders include Miller Electric, Lincoln Electric, Hobart Welding Products, YesWelder, and Eastwood.

These brands are well known for stable arc performance, durable components, and strong support for home and DIY welding.

A 110V welder can reliably weld up to 1/8 inch (3 mm) steel with proper joint preparation and technique.

Thicker metal is possible using multiple passes, but penetration and duty cycle limits become more noticeable on standard household power.

Yes. A 110V stick welder is effective for light repairs, outdoor welding, and simple steel projects.

It works best for short welds and common electrodes such as 6013 or smaller 7018 rods, but it is not designed for long, continuous welds or heavy structural work.

Most 110V welders require 2,000 to 3,500 watts, while 4,000 watts or more is recommended to handle the startup surge safely.

Insufficient power can cause breaker trips, unstable arcs, and inconsistent weld quality.

.030-inch wire is better for most 110V welders.

It requires lower amperage, provides better control on thin steel, and reduces the risk of burn-through.

.035-inch wire generally performs better on higher-output machines or when welding thicker material.