Aluminum and steel are two of the most widely used metals in the world, strong, durable, and versatile in their own ways. But they’re also very different. Aluminum is lightweight and corrosion-resistant, while steel is tough and strong under high stress.

That’s why fabricators and engineers often ask a critical question: Can you weld aluminum to steel?

The short answer, not directly. Welding these two metals together using traditional fusion techniques leads to brittle, weak joints that are prone to cracking and corrosion. But that doesn’t mean it’s impossible. With the right methods, materials, and understanding of metallurgy, aluminum and steel can be joined effectively, just not in the same way aluminum is welded to aluminum or steel to steel.

In this guide, we’ll explore why these metals don’t fuse easily, the science behind the difficulty, and the modern techniques that make aluminum-to-steel joining possible in manufacturing, automotive, and aerospace applications.

Why Welding Aluminum to Steel Is So Difficult

Before we get into the solutions, it’s important to understand the problem. Aluminum and steel have drastically different properties, which makes direct fusion welding almost impossible.

1. Different Melting Points

- Aluminum melts at around 1,220°F (660°C).

- Steel melts at approximately 2,500°F (1,370°C).

When you apply heat to weld them, aluminum melts long before steel even begins to fuse, resulting in weak, inconsistent joints or holes in the aluminum section.

2. Formation of Brittle Compounds

When aluminum and steel are melted together, they form intermetallic compounds like iron aluminide. These compounds are extremely brittle and can crack easily, rendering the weld useless.

3. Oxidation and Contamination

Both metals oxidize differently. Aluminum forms a stubborn oxide layer that resists fusion, while steel’s oxide reacts with aluminum to create contamination at the weld interface.

4. Thermal Expansion Differences

Aluminum expands nearly twice as much as steel when heated. As the joint cools, the difference in expansion causes internal stress and eventually leads to cracking.

Fusion Welding vs. Solid-State Welding

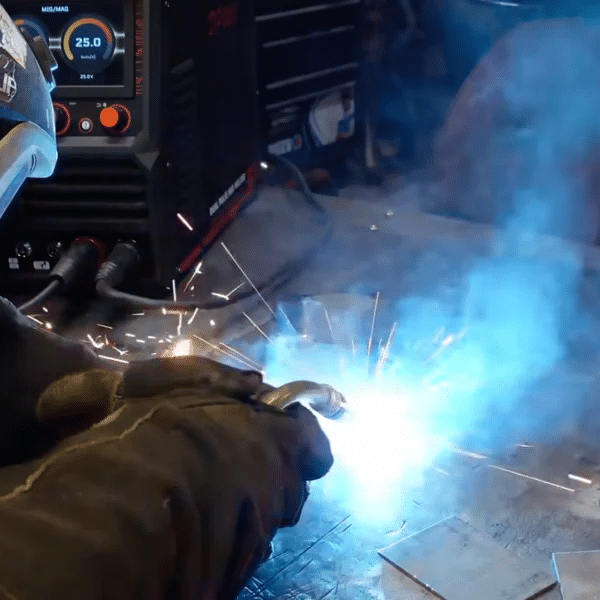

Traditional welding methods like TIG welder or MIG welder rely on fusion, where both metals melt and fuse. This approach fails for aluminum and steel because of their incompatible properties.

That’s where solid-state welding comes in, a process where metals are joined without melting, usually through pressure and friction-based heat.

Techniques for Joining Aluminum to Steel

While direct welding isn’t ideal, several proven methods can successfully join these metals, depending on the application.

1. Bimetallic Transition Inserts

This is the most practical and widely used method.

A bimetallic transition insert is a pre-bonded piece of aluminum and steel, often made using explosion welding or friction stir welding. The insert acts as a “bridge” between the two materials.

How It Works:

- The aluminum side of the insert is welded to the aluminum component (TIG or MIG).

- The steel side of the insert is then welded to the steel part using conventional steel welding methods.

This method is commonly used in:

- Shipbuilding and marine structures

- Automotive body panels

- Heat exchangers and pressure vessels

Advantages:

- Reliable, strong bond.

- Minimizes risk of brittle intermetallic layers.

- Can be performed with standard welding equipment suppliers.

2. Friction Stir Welding (FSW)

Friction stir welding is a solid-state process that joins metals below their melting point.

How It Works:

A rotating tool applies pressure and frictional heat to the joint, softening both materials and stirring them together at the interface.

Why It Works:

Since it avoids melting, it prevents brittle intermetallic compounds from forming. The resulting joint is stronger and more ductile than one created by fusion welding.

Applications:

- Aerospace and automotive manufacturing.

- High-strength structural components.

Limitations:

- Requires specialized FSW machines.

- Best suited for flat or linear joints.

3. Explosion Welding

As the name suggests, explosion welding uses controlled explosive energy to bond metals together at high velocity.

How It Works:

An explosive charge propels one metal (usually aluminum) onto another (steel) with extreme force. The impact generates localized heat and pressure that fuse the metals at a molecular level, without melting them.

Advantages:

- Produces very strong, clean joints.

- Ideal for creating bimetallic transition plates.

- Can join large surface areas quickly.

Drawbacks:

- Dangerous and expensive.

- Requires highly specialized facilities.

4. Adhesive Bonding

For applications that don’t require extreme strength, industrial adhesives offer a simple and cost-effective way to bond aluminum to steel.

How It Works:

Epoxy or polyurethane-based adhesives are applied to clean, pre-treated surfaces. Once cured, they form a durable, corrosion-resistant joint.

Pros:

- No heat required.

- Lightweight and easy to apply.

- Works well for thin sheets and assemblies.

Cons:

- Not suitable for high-load or high-temperature environments.

- Requires perfect surface preparation for best results.

5. Mechanical Fastening

Sometimes, the simplest method works best, bolting, riveting, or screwing aluminum to steel.

Why It’s Still Popular:

- No heat distortion.

- Easy to disassemble for maintenance.

- Works great for prototypes or temporary assemblies.

To prevent galvanic corrosion (which occurs when aluminum and steel come into contact with each other in the presence of an electrolyte), always use insulating washers, coatings, or sealants between the metals.

Preventing Galvanic Corrosion

When aluminum and steel are joined, they create an electrochemical cell, aluminum acts as the anode and corrodes faster than steel.

Prevention Tips:

- Use coatings or paint on both materials.

- Apply dielectric grease or sealant to joints.

- Use isolating washers or gaskets between metals.

- Select proper adhesives or inserts designed for dissimilar metals.

Proper protection ensures long-term durability and prevents corrosion-related failures.

Tips for Success

If you’re working on a project that involves both metals, here’s how to ensure reliable results:

- Always clean both surfaces before bonding.

- Avoid direct heat welding unless using a transition material.

- Use argon or argon-helium mixtures for TIG or MIG sections involving aluminum.

- Prevent direct metal-to-metal contact to reduce corrosion risk.

- Consider post-weld coating or painting for extra protection.

Real-World Applications

You might be surprised at how often aluminum and steel are joined in modern manufacturing:

- Automotive Industry: Lightweight aluminum panels bonded to steel frames for fuel efficiency.

- Shipbuilding: Steel hulls joined with aluminum superstructures to reduce top weight.

- Construction: Mixed-metal frameworks in bridges and buildings.

- Energy Sector: Transition joints in heat exchangers, pipelines, and offshore platforms.

Each of these relies on one or more of the advanced joining techniques described above.

So, can you weld aluminum to steel? Technically, yes, but not in the traditional sense. Direct fusion welding doesn’t work because of the metals’ vastly different properties. Instead, engineers rely on solid-state processes like friction stir or explosion welding, transition inserts, or mechanical and adhesive bonding to bridge the gap between the two.

With the right approach, joining aluminum and steel isn’t just possible, it’s a key enabler of modern, lightweight, high-performance designs used across industries—the secret lies in understanding the science and applying the right technique for the job.

Related Reading

1.Can You Weld Aluminum to Aluminum?

Clean prep, correct filler, and heat control make or break an aluminum-to-aluminum weld. Here’s how to do it right.

2.Can You Weld Steel to Aluminium?

Steel and aluminium behave very differently under heat. Learn the risks, common workarounds, and when you should not attempt it.

3.Aluminum Welding Guide

From surface cleaning to heat control, this guide walks you through how to get strong, clean aluminum welds with fewer cracks.

4.MIG vs TIG Welding: Which Process Is Better for Your Job?

Learn when to use MIG for speed and when TIG is worth it for precision, especially on thinner or more sensitive metals.

5.Why Welding Aluminum to Steel Is So Difficult?

Aluminum and steel have very different melting points and form brittle layers at the joint. Here’s what actually happens — and safer alternatives.