Steel and aluminium, two powerhouse materials that dominate industries from construction to aerospace. Steel is celebrated for its strength and toughness, while aluminium is prized for its lightness and corrosion resistance. Combining them can unlock the best of both worlds: durability and reduced weight.

That leads to one of the most common questions in metal fabrication, Can you weld steel to aluminum?

The short answer: not by conventional means. These metals don’t fuse naturally because of fundamental differences in their physical and chemical properties. But that doesn’t mean joining them is impossible. Engineers and welders have developed several creative and reliable ways to connect steel and aluminium, without relying on traditional fusion welding.

In this guide, we’ll explore why it’s difficult, the science behind it, and the most effective methods used today to bond steel to aluminium safely and securely.

Why Steel and Aluminium Don’t Weld Easily

At first glance, welding steel to aluminium might seem straightforward. After all, both are metals, and welding joins metals, right? The challenge is that they behave very differently under heat.

1. Vastly Different Melting Points

- Aluminium melts at 1,220°F (660°C)

- Steel melts at about 2,500°F (1,370°C)

When heat is applied, aluminium liquefies long before steel begins to melt. This imbalance makes it nearly impossible to form a consistent fusion zone.

2. Formation of Brittle Compounds

When molten aluminum comes into contact with steel, iron-aluminum intermetallic compounds form at the joint. These are extremely brittle, causing cracks and weak welds that can’t handle stress or vibration.

3. Oxide Layers and Contamination

Aluminium forms an oxide layer almost instantly when exposed to air. This layer resists melting and interferes with bonding. Steel, on the other hand, develops iron oxide (rust) that behaves differently. The combination leads to poor adhesion and impurities in the weld zone.

4. Mismatched Thermal Expansion

Aluminium expands almost twice as much as steel when heated. As the joint cools, these differences in contraction create stress, warping, or complete weld failure.

Why Traditional Welding Fails

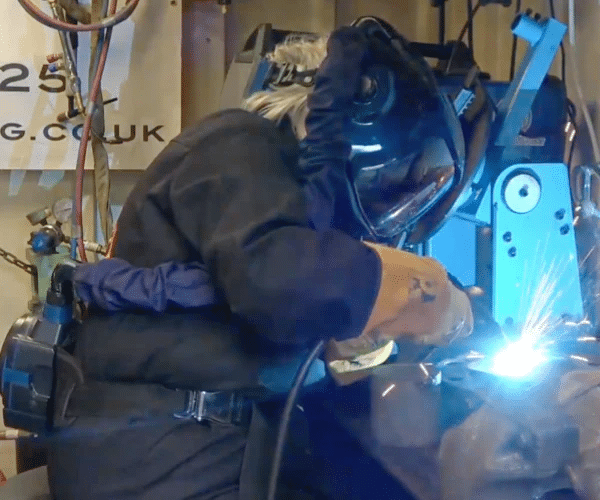

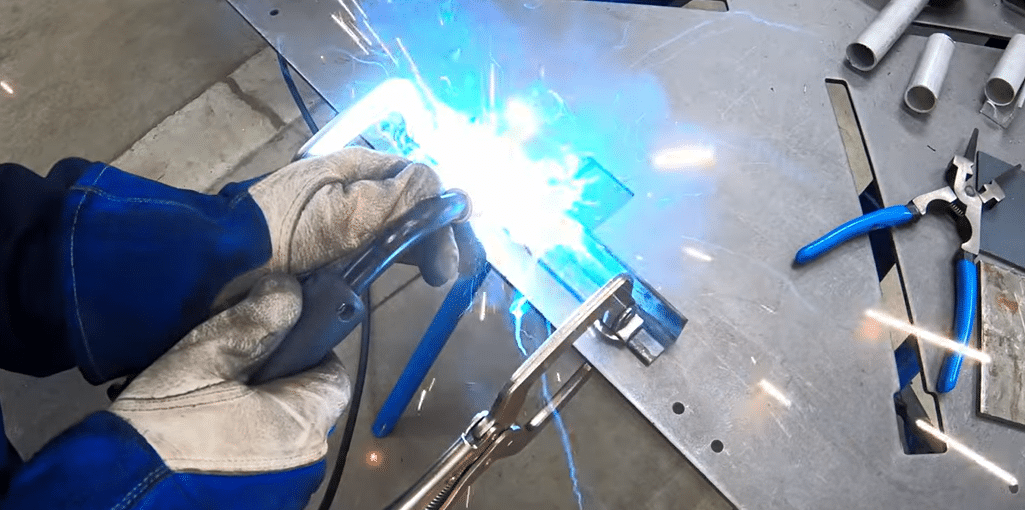

Fusion welding methods like TIG welding, MIG welding, or Stick welding rely on melting the base metals and filler to fuse them. In the case of steel and aluminium, this causes immediate chemical incompatibility.

The molten aluminium dissolves iron from steel, leading to the formation of brittle intermetallic phases. These compounds act like glass, hard but prone to cracking under even minor loads.

In short, direct welding of steel to aluminium isn’t feasible using conventional techniques. However, there are alternative methods that can successfully join them without melting either material.

Modern Techniques to Join Steel and Aluminium

To overcome the limitations of fusion welding, industries use solid-state or indirect joining techniques. These rely on pressure, friction, or adhesives rather than melting. Let’s look at the most reliable methods.

1. Bimetallic Transition Inserts

The most practical solution is to use a bimetallic transition insert, sometimes called a “bi-metal adapter.”

These inserts are specially manufactured pieces where steel and aluminum are already bonded together using techniques such as explosion welding or friction stir welding.

How It Works:

- The aluminum side of the insert is welded to your aluminum part using TIG or MIG welding.

- The steel side of the insert is welded to the steel part using standard steel welding techniques.

This way, the metals never directly fuse, yet the connection remains strong.

Benefits:

- Clean, reliable joint.

- Prevents brittle layer formation.

- Uses existing welding tools and processes.

Common Applications:

- Shipbuilding (aluminium decks on steel hulls).

- Heat exchangers.

- Automotive frames and components.

2. Friction Stir Welding (FSW)

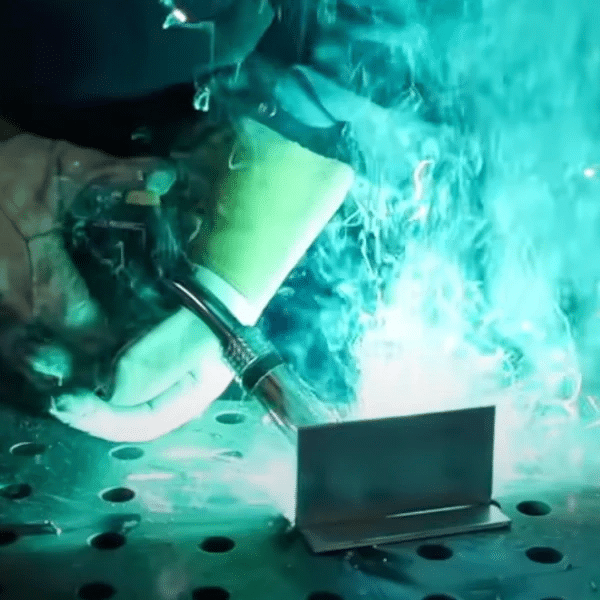

This is one of the most advanced solid-state welding methods. Unlike conventional welding, friction stir welding doesn’t melt the metals, it softens and mixes them under controlled pressure and frictional heat.

How It Works:

A rotating tool pin moves along the joint line, generating heat through friction. This heat softens the metals, and the mechanical stirring action blends them together without creating a molten pool.

Advantages:

- Strong, defect-free joints.

- No intermetallic compound formation.

- Excellent for large or linear joints.

Limitations:

- Requires specialized equipment, available from leading welding equipment suppliers.

- Works best on flat panels or sheets.

Industries Using It:

- Aerospace.

- High-performance automotive manufacturing.

- Rail and marine applications.

3. Explosion Welding

Explosion welding uses controlled explosive energy to bond aluminium and steel together. It’s a high-velocity, solid-state process that forms a molecular bond without melting the metals.

How It Works:

A layer of aluminium is placed over steel with a small gap. An explosive charge is detonated, propelling the aluminium onto the steel surface at extremely high speed. The resulting impact creates a wavy, interlocked interface that fuses the metals.

Advantages:

- Produces very strong, clean joints.

Suitable for large surface areas. - Commonly used to create bimetallic transition plates.

Disadvantages:

- Expensive and highly specialized.

- Requires safety and control measures due to explosive use.

4. Adhesive Bonding

When extreme strength isn’t required, adhesive bonding offers a flexible, lightweight solution for joining steel to aluminium.

How It Works:

Special industrial adhesives, usually epoxy-based, are applied between pre-treated surfaces. Once cured, they form a durable, corrosion-resistant bond.

Advantages:

- No heat distortion.

- Excellent corrosion resistance.

- Perfect for thin sheets or complex shapes.

Disadvantages:

- Lower mechanical strength compared to welding.

- Surface cleanliness and preparation are critical.

Used In:

- Automotive body panels.

- Consumer electronics.

- Lightweight structural assemblies.

5. Mechanical Fastening

Mechanical methods like riveting, bolting, or screwing are still widely used for mixed-metal assemblies.

Why It Works:

- No heat required.

- Easy to assemble and disassemble.

- Ideal for prototypes and modular structures.

However, since steel and aluminium are electrochemically dissimilar, galvanic corrosion can occur at the joint.

Prevention Tips:

- Use insulating materials like nylon washers or gaskets.

- Apply protective coatings or sealants.

- Ensure joints are kept dry and sealed from moisture.

Preventing Galvanic Corrosion

Whenever steel and aluminium come into contact, especially in moist environments, galvanic corrosion can occur. The aluminium becomes the anode and corrodes faster than steel.

To Prevent This:

- Coat or paint both materials.

- Use dielectric grease or sealants to isolate the metals.

- Avoid direct contact by inserting insulating barriers.

- Regularly inspect and maintain joints, especially outdoors.

Key Preparation Steps

Whether you use adhesives, inserts, or fasteners, preparation is crucial:

- Clean surfaces with acetone to remove oils and dirt.

- Remove oxide layers from aluminium with a stainless steel brush.

- Use correct filler materials for any aluminium-side welds (ER4043 or ER5356).

- Preheat thick sections to reduce stress and improve bonding.

Real-Life Applications

Joining steel to aluminium isn’t just theoretical, it’s everywhere:

- Automotive Industry: Aluminium panels bonded to steel frames to reduce weight and improve fuel efficiency.

- Shipbuilding: Lightweight aluminium decks attached to steel hulls.

- Construction: Mixed-metal bridges and building frameworks.

- Energy Industry: Bimetallic joints used in pressure vessels and heat exchangers.

These examples prove that while direct welding is impractical, hybrid joining methods make aluminium-steel combinations both possible and reliable.

So, can you weld steel to aluminium? Technically, not with standard welding techniques. The two metals don’t fuse properly due to different melting points and chemical reactions that form brittle compounds.

But thanks to advanced methods like bimetallic inserts, friction stir welding, explosion welding, and adhesives, you can join them effectively. The right method depends on your project’s strength, cost, and environmental requirements.

With careful preparation and corrosion prevention, steel and aluminium can work together seamlessly — combining strength with lightness in ways that push engineering boundaries.

Related Articles

1. Can You Weld Aluminum to Aluminum?

This article explains the techniques and methods used to weld aluminum successfully, including common challenges and expert tips on using TIG and MIG welding. It also covers preparation techniques, choosing the right filler material, and troubleshooting common issues.

2. Can You Weld Aluminum to Steel?

This article explores the challenges and modern methods for joining aluminum to steel, such as bimetallic transition inserts, friction stir welding, and adhesive bonding. It also discusses how to prevent galvanic corrosion and achieve strong, reliable joints between these dissimilar metals.

3.Aluminum Welding Guide

From surface cleaning to heat control, this guide walks you through how to get strong, clean aluminum welds with fewer cracks.

4.MIG vs TIG Welding: Which Process Is Better for Your Job?

Learn when to use MIG for speed and when TIG is worth it for precision, especially on thinner or more sensitive metals.