Welding is a skilled trade that demands precision, technique, and most importantly, proper safety equipment. Among all the protective gear a welder uses, gloves are perhaps the most critical piece of equipment, serving as the primary barrier between your hands and the intense heat, sparks, and molten metal that characterize welding work. Choosing the best welding gloves isn’t just about comfort, it’s about protecting your livelihood and ensuring you can continue working safely for years to come.

The hands are a welder’s most valuable tools, containing intricate networks of nerves, tendons, and muscles that enable the precise movements essential for quality welding work. A single burn or injury can sideline a professional welder for weeks or even permanently affect their ability to work. This makes selecting the right welding gloves not just a matter of compliance with safety regulations, but a crucial investment in your career longevity.

Understanding Your Welding Process Requirements

Different welding processes generate varying levels of heat, require different levels of dexterity, and present unique hazards that influence glove selection. Understanding these distinctions is crucial for selecting the most suitable welding gloves for your specific applications.

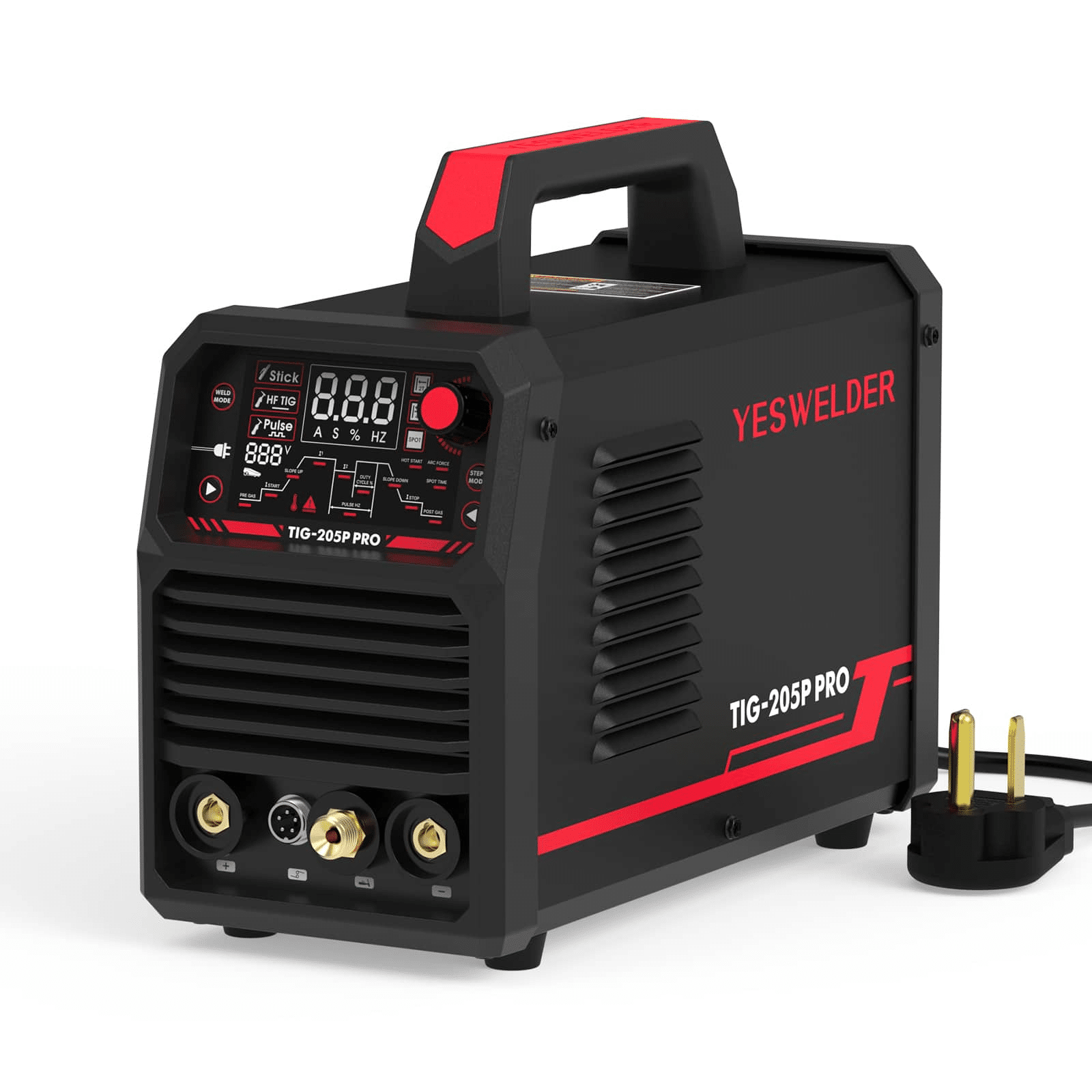

TIG (Tungsten Inert Gas) Welding demands the highest level of precision and dexterity. TIG welders often work with thin materials and require fine motor control to manipulate filler rods while maintaining precise torch angles. The best welding gloves for TIG work typically feature thinner leather construction, often made from soft deerskin or thin cowhide, allowing maximum tactile feedback while still providing adequate heat protection.

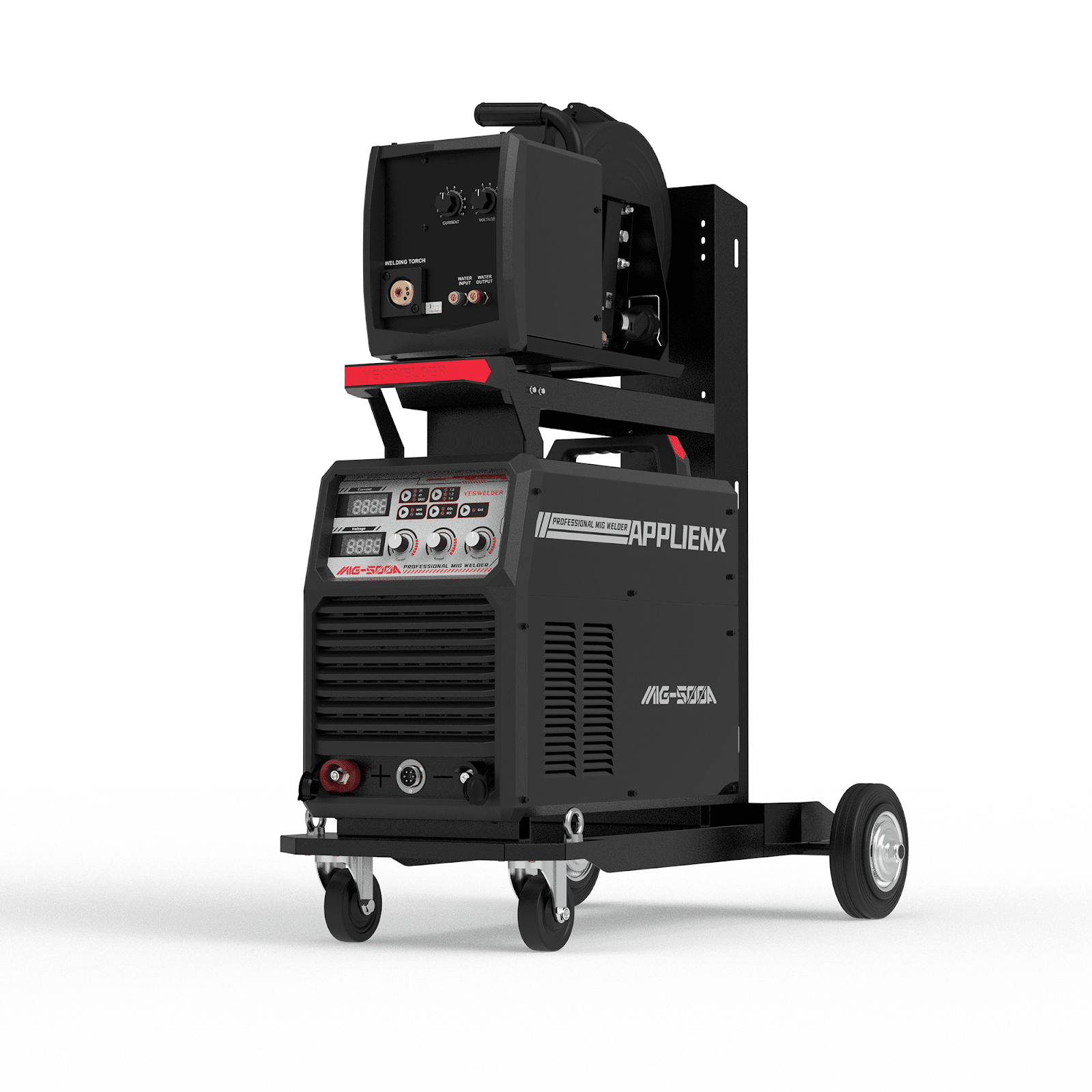

MIG (Metal Inert Gas) Welding generates more heat and spatter than TIG welding, requiring gloves with greater heat resistance and coverage. MIG welders require gloves that strike a balance between protection and sufficient dexterity to handle the welding gun effectively. Medium-weight leather gloves with reinforced palms and fingers typically serve MIG welders well.

Stick Welding (SMAW) produces the most intense heat and heaviest spatter, necessitating the most robust protection. Stick welders require thick, heavy-duty leather gloves that can withstand prolonged exposure to high temperatures and resist punctures from flying slag and spatter.

Flux-Cored Welding shares similarities with MIG welding but often produces more spatter, requiring gloves with enhanced spatter resistance and extended cuff protection.

Essential Features of Quality Welding Gloves

When evaluating the best welding gloves, several key features distinguish superior products from basic alternatives. These characteristics directly impact both safety and work performance.

Heat Resistance stands as the primary consideration. Quality welding gloves must withstand temperatures ranging from 500°F to over 1000°F, depending on the welding process. Look for gloves with proper heat resistance ratings and consider the duration of heat exposure your work typically involves.

Dexterity and Fit significantly impact welding quality and worker fatigue. Gloves that are too bulky compromise precision, while gloves that are too tight restrict blood flow and cause hand fatigue. The best welding gloves strike an optimal balance, protecting without compromising the fine motor control essential for producing quality welds.

Durability affects both safety and cost-effectiveness. Premium welding gloves resist wear, punctures, and heat degradation longer than inferior alternatives. While higher-quality gloves may cost more initially, their extended lifespan often makes them more economical in the long run.

Comfort Features include proper ventilation, moisture-wicking linings, and ergonomic designs that reduce hand fatigue during extended welding sessions. Comfortable gloves encourage consistent use, which is crucial for maintaining safety standards.

Material Selection

The choice of leather and construction materials significantly determines the performance characteristics of the glove. Understanding these materials helps welders select the best welding gloves for their specific needs.

Cowhide remains the most popular choice for welding gloves due to its excellent balance of heat resistance, durability, and cost-effectiveness. Split cowhide leather offers good heat resistance and is more affordable, while grain cowhide provides superior durability and comfort but at a higher cost.

Pigskin offers exceptional dexterity and comfort, making it ideal for precision welding work. Pigskin gloves often feature superior tactile feedback and remain softer longer than other leather types, though they may not provide the same level of heat resistance as thicker cowhide options.

Deerskin provides the ultimate in dexterity and comfort for precision welding applications. While more expensive than other leather types, deerskin gloves offer unmatched tactile sensitivity for TIG welding and other applications requiring fine motor control.

Specialty Materials including Kevlar threading, aluminized fabrics, and heat-resistant synthetic materials appear in premium welding gloves designed for extreme conditions or specialized applications.

Size and Fit Considerations

Proper sizing is crucial for both safety and performance when selecting the best welding gloves. Ill-fitting gloves can compromise dexterity, cause premature fatigue, and even create safety hazards.

Gloves that are too large can slip during critical moments, potentially exposing skin to heat and sparks. Oversized gloves also reduce tactile feedback and precise control, negatively impacting weld quality. Conversely, gloves that are too small restrict blood circulation, cause rapid hand fatigue, and may split or tear under stress.

To determine proper sizing, measure your hand circumference at its widest point, typically across the knuckles. Most manufacturers provide sizing charts that correlate hand measurements with glove sizes. When possible, try gloves on before purchasing, ensuring adequate finger length while maintaining a snug but not restrictive fit across the palm and wrist.

Consider the thickness of any liner gloves or hand protection you typically wear underneath welding gloves, as this affects sizing requirements. Some welders prefer slightly larger gloves to accommodate liner gloves during extended welding sessions or in cold environments.

Safety Standards and Certifications

Professional welding gloves should meet or exceed established safety standards that ensure minimum performance requirements for heat resistance, durability, and protection. Understanding these standards helps identify the best welding gloves for professional use.

The American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) have established standards for welding protective equipment. Look for gloves that meet ANSI/ISEA 105 standards for cut resistance and heat protection.

European CE marking indicates compliance with European safety standards, while CSA approval signifies adherence to Canadian safety requirements. These certifications provide assurance that gloves have undergone rigorous testing for safety and performance characteristics.

Specialized Glove Types for Specific Applications

Different welding environments and applications may require specialized glove designs that go beyond standard welding gloves. Understanding these options helps ensure you select the best welding gloves for your specific needs.

High-Heat Applications may require gloves with aluminized surfaces or specialized heat-resistant coatings that reflect radiant heat away from the hands. These gloves are essential for welding heavy structural steel or working in high-temperature environments.

Chemical-Resistant Gloves become necessary when welding operations involve exposure to acids, solvents, or other chemicals. These gloves combine welding protection with chemical resistance, though they may sacrifice some dexterity.

Cut-Resistant Gloves incorporate materials like Kevlar or other high-strength fibers to protect against sharp edges and metal fragments commonly encountered in welding fabrication work.

Maintenance and Care for Longevity

Proper maintenance significantly extends glove life and maintains protective properties, making quality gloves more cost-effective over time. The best welding gloves will last longer and provide better protection when properly cared for.

Regular inspection for holes, thin spots, or heat damage should be part of every welder’s routine. Small holes can quickly expand and compromise protection, while heat-damaged leather loses its protective properties and should be replaced immediately.

Proper storage away from direct sunlight and extreme temperatures helps preserve leather flexibility and extends glove life. Avoid storing gloves in damp conditions, which can promote mold growth and leather degradation.

Cleaning welding gloves requires special attention to avoid damaging protective properties. Use mild soap and warm water for basic cleaning, avoiding harsh chemicals or detergents that can strip protective treatments from the leather.

Cost Considerations and Value Assessment

While the initial cost of premium welding gloves may seem high, evaluating total value includes factors beyond purchase price. The best welding gloves often provide superior value through extended lifespan, better protection, and improved work performance.

Calculate cost per hour of use rather than simply comparing purchase prices. Premium gloves that last twice as long as economy alternatives often provide better value despite higher initial costs. Additionally, consider the potential costs of hand injuries, which can far exceed the price difference between quality and economy gloves.

Factor in productivity benefits when assessing glove value. Gloves that provide better dexterity and comfort can improve work quality and reduce fatigue, potentially increasing earning capacity over time.

Making Your Final Selection

Choosing the best welding gloves requires balancing multiple factors including protection level, dexterity requirements, durability expectations, and budget constraints. Start by clearly identifying your primary welding processes and their specific requirements.

Consider purchasing different glove types for different applications rather than trying to find one glove that works for everything. Many professional welders maintain separate gloves for precision work, heavy-duty applications, and general fabrication tasks.

Don’t compromise on quality when it comes to safety equipment. Your hands are irreplaceable, and investing in proper protection is essential for a long, productive welding career. Research manufacturers’ reputations, read reviews from other professionals, and choose gloves from companies with established track records in welding safety equipment.

Final Thoughts

Selecting the best welding gloves is a critical decision that impacts both safety and work performance. By understanding your specific welding requirements, evaluating essential features, considering material options, and ensuring proper fit, you can choose gloves that provide optimal protection while enabling the dexterity needed for quality welding work.

Remember that welding gloves are not just protective equipment, they’re professional tools that directly influence your ability to perform quality work safely and efficiently. Invest in quality gloves appropriate for your specific applications, maintain them properly, and replace them when they show signs of wear or damage.

Your hands are your livelihood as a welder. Protecting them with the best welding gloves available is not just smart, it’s essential for a successful, long-term welding career. Take the time to research your options, understand your needs, and choose gloves that will serve you well for years to come.

FAQ – Welding Gloves

Q1: Can I use TIG gloves for MIG welding? TIG gloves are designed for maximum dexterity and thinner materials, typically made from soft deerskin or pigskin. While you can use them for MIG welding in light applications, they don’t provide enough heat and spatter resistance for most MIG work. For safety and durability, it’s better to use dedicated MIG welding gloves with reinforced palms and thicker cowhide.

Q2: How long do welding gloves last?

The lifespan of welding gloves depends on frequency of use, type of welding, and glove quality. On average, professional welders may replace gloves every few weeks to a few months. High-quality gloves made from durable leather and reinforced stitching last significantly longer than budget options, especially if maintained and stored properly.

Q3: Are welding gloves fireproof? Welding gloves are fire-resistant, not fireproof. They are designed to withstand sparks, spatter, and high heat, but prolonged or direct exposure to flames will eventually damage the gloves. Always avoid contact with open flames and replace gloves if you notice burn-through, holes, or stiffened leather from heat damage.