In metal fabrication, welding isn’t just about melting two pieces of metal together, it’s about joining them in the strongest, most efficient way for the task at hand. Different joint designs determine how force travels through a welded structure, how easily it can be produced, and how long it lasts under stress.

One of the most common and versatile designs used in industries like automotive, construction, and manufacturing is the lap weld. This joint is known for its simplicity, ease of alignment, and excellent strength when done correctly.

In this detailed guide, we’ll explore everything you need to know about welding lap joints, from how they work to their applications, advantages, and pro tips for achieving clean, durable welds.

What are lap joints used for?

A lap weld is a type of joint where two pieces of metal overlap each other and are welded at the edges.

This design is simple yet effective, it distributes load across a broad area and allows welders to connect thin or dissimilar materials without burning through the base metal.

To ensure quality, sourcing materials from a reliable welding equipment supplier can significantly improve results.

Lap welds are used in nearly every major industry. Here are a few examples:

- Automotive and Transport

Used in car body panels, exhaust systems, and chassis frames. Spot or MIG lap welds ensure strength and durability without adding excessive weight. - Construction and Fabrication

Found in structural components, HVAC ducting, and steel framing. Lap joints make assembly faster and simpler. - Aerospace

Used in thin aluminum and titanium sheet structures that require strength with minimal distortion. - Electronics and Electrical

Copper and aluminum lap welds are used for high-conductivity connections in motors and switchgear. - Shipbuilding and Marine

Applied to join hull plates and structural components, often double-sided for corrosion resistance.

In general, lap welds are also common in sheet metal fabrication, structural frames and reinforcements, and pipes or pressure vessels.

The welds can be placed on one or both sides of the overlap, depending on the strength required.

Understanding the Welding Lap Joint

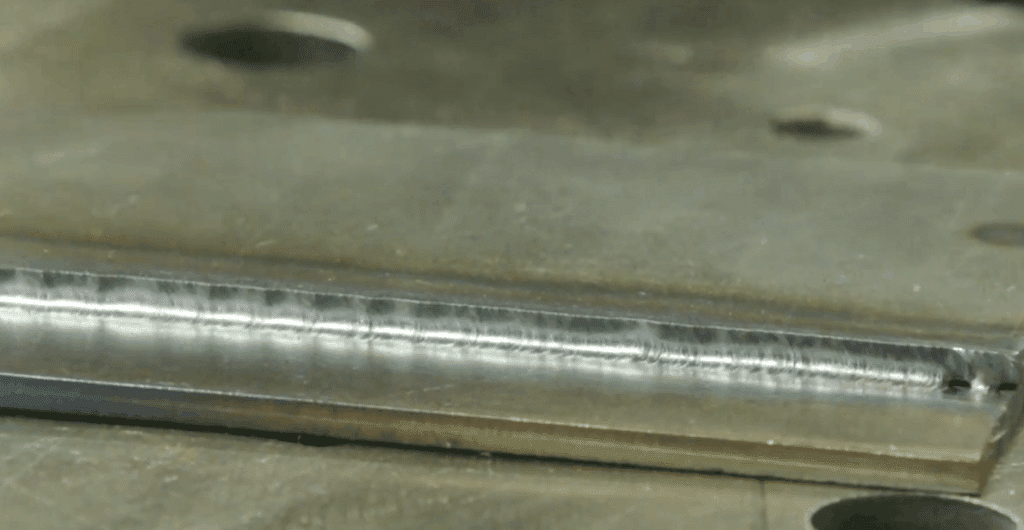

The welding lap joint is formed by overlapping two plates or sheets of metal and applying a weld bead along the edge (or edges). The weld may be continuous or intermittent, depending on the load conditions and design requirements.

Visually, the joint resembles a stack, one plate sitting partially over another, creating a lap-like structure.

Typical Dimensions:

- Overlap length: 3x the thickness of the thinner sheet (minimum).

- Weld leg size: Equal to or slightly smaller than the sheet thickness.

Common Variants:

- Single Lap Joint: Weld applied on one side of the overlap.

- Double Lap Joint: Welds are applied on both sides for added strength

What Are the Three Types of Lap Joints?

Lap joints come in several forms depending on how the overlapping pieces are joined and the strength required. While the basic concept remains the same—one plate overlapping another—welders classify lap joints into three main types: single lap joint, double lap joint, and fillet lap joint.

1. Single Lap Joint

A single lap joint is the simplest form. Two pieces of metal overlap each other and are welded, riveted, or bonded on one side only.

- Advantages: Easy to prepare and ideal for thin sheets.

- Common Uses: Sheet metal work, light fabrication, and temporary structures.

- Limitation: Because the load is offset, it can introduce bending stress under tension.

2. Double Lap Joint

A double lap joint uses three layers of material—one sandwiched between two outer plates. Welds or fasteners are applied on both sides of the center piece.

- Advantages: Provides greater strength and distributes stress more evenly.

- Common Uses: Heavy-duty fabrication, automotive frames, and pressure vessels.

- Benefit: Excellent resistance to shear and bending, making it suitable for high-stress applications.

3. Fillet Lap Joint

A fillet lap joint combines the lap configuration with a fillet weld along the overlapping edges. This type is extremely common in both MIG and TIG welding.

- Advantages: Simple, strong, and easy to perform.

- Common Uses: Automotive panels, piping, HVAC ducting, and general fabrication.

- Note: Welds can be placed on one or both sides to achieve the desired strength.

Lap Weld vs. Fillet Weld

A lap weld is a joint where two metal pieces overlap and are welded along the edges, while a fillet weld is used to join two surfaces that meet at roughly a right angle, forming a triangular weld bead.

Though both are common in fabrication and construction, they differ in geometry, load capacity, and typical use.

1. Joint Configuration

In a lap weld, one piece of metal overlaps the other, creating a broad contact area that effectively distributes shear stress.

A fillet weld, on the other hand, connects two members at an angle—such as in T-joints, corner joints, or lap joints—where the weld fills the space between the two surfaces.

2. Strength and Load Direction

Lap welds are primarily designed to resist shear forces along the plane of the overlap, making them suitable for sheet metal, frames, and pipe assemblies.

Fillet welds can withstand shear, tensile, and compressive loads, providing excellent all-round strength for structural steel and heavy-duty components.

3. Typical Applications

Lap welds are used in automotive panels, HVAC ducting, pressure vessels, and lightweight frames, where ease of alignment and clean seams are important.

Fillet welds are common in structural beams, shipbuilding, machinery frames, and pipe connections, where high load capacity and corner reinforcement are required.

4. Appearance and Technique

A lap weld typically forms a smooth seam along the edge of the overlap and may use one or two weld beads depending on the required strength.

A fillet weld produces a triangular cross-section, which can be single- or double-sided. Both can be performed using MIG, TIG, or stick welding, though lap welds are often preferred for thinner materials due to lower heat concentration.

5. Summary

While lap welds are simple, clean, and efficient for overlapping joints, fillet welds provide versatility and structural integrity for angled connections.

In practice, many lap joints actually use fillet welds along the edges—combining the advantages of both designs to achieve strong, stable, and durable results.

How to Make a Lap Weld Step by Step

Creating a strong, clean lap weld requires precision, control, and proper setup. Here’s a breakdown of the process:

1. Preparation

- Clean both surfaces to remove rust, paint, oil, or dirt.

- Align the metals so that one overlaps the other evenly, typically by ½ inch to several inches, depending on the project.

- Clamp the pieces securely to prevent shifting during welding.

2. Choose the Right Welding Process

Lap joints can be made using several processes, including:

MIG (GMAW): Fast and efficient for sheet metal.A MIG welder is ideal for projects requiring high speed and smooth welds.

TIG (GTAW): Provides precision and control for thin or delicate materials.A TIG welder is perfect for achieving clean, high-quality welds on thin metals.

For TIG: Grind off the mill scale before TIG welding.

Technique:

- Keep 10-15 degrees from vertical in the direction of travel.

- The metal edge will melt quicker than the base metal. Keep angled more towards base plate and heat up until you see the edge start to wet in to the puddle.

Stick (SMAW): Good for thicker plates or outdoor welding.A Stick welder is a versatile tool for heavy-duty applications, offering reliable results even in challenging conditions.

Spot Welding: Common in automotive and sheet metal work for clean, rapid joints.

3. Set the Correct Parameters

- Amperage: Low to medium range for thin materials; higher for thick plates.

- Travel speed: Moderate, too fast reduces penetration, too slow causes burn-through.

- Shielding gas: Argon or argon-CO₂ mix (for MIG/TIG).

4. Welding Technique

- Maintain a 15–20° gun angle toward the direction of travel.

- Use a weaving motion for thicker materials to ensure full fusion.

- For thin sheets, use a straight bead to minimize heat distortion.

5. Inspection and Finishing

- Check the weld bead for smoothness, evenness, and penetration.

- Grind or polish if aesthetics matter.

- Apply anti-corrosion coating or paint for longevity.

Lap Weld Symbols in Blueprints

In welding blueprints, the lap weld is represented by a fillet weld symbol placed on the reference line of the welding symbol.

- Arrow side indicates where the weld is applied.

- Size and length are specified on the drawing.

- If both sides of the lap joint are welded, a double fillet weld symbol is used.

Understanding these symbols ensures proper communication between design engineers and welders on the shop floor.

Advantages of Lap Welds

Lap welds are popular for good reasons. They offer flexibility and reliability across a wide range of applications.

1. Easy to Set Up

Lap joints don’t require complex beveling or edge preparation, just overlap and weld.

2. Suitable for Thin Materials

Perfect for sheet metal and light fabrication where deep penetration could cause distortion or holes.

3. High Strength

When welded correctly, lap joints distribute loads over a large area, providing excellent shear strength.

4. Dissimilar Metal Compatibility

Ideal for joining different materials or thicknesses, such as steel to stainless steel or aluminum to copper (with proper filler).

5. Minimal Alignment Issues

The overlap design naturally ensures better alignment than butt or edge joints.

Disadvantages of Lap Welds

Despite their usefulness, lap joints also have some limitations:

1. Prone to Crevice Corrosion

The overlapping area can trap moisture, leading to rust if not properly sealed or coated.

2. Limited Aesthetic Appeal

Lap welds may look bulky or uneven on visible surfaces.

3. Uneven Stress Distribution

The offset nature of the joint can cause bending stress under heavy loads.

4. Difficult to Inspect

The hidden overlap makes it harder to detect internal defects without advanced testing.

Best Practices for Strong Lap Welds

- Use the Correct Overlap — A minimum of 3x the thickness of the thinner sheet ensures proper load distribution.

- Ensure Clean Surfaces — Even small amounts of oil or rust can cause poor fusion.

- Avoid Overheating — Excessive heat can distort or weaken thin metals.

- Weld Both Sides if Possible — Balances stress and increases strength.

- Seal the Edges — Apply paint, primer, or sealant to prevent corrosion in the overlap area.

Testing Lap Weld Strength

Engineers use various testing methods to ensure lap joints meet strength and quality standards:

- Shear Testing: Measures resistance to sliding forces.

- Peel Testing: Checks resistance to separation.

- Tensile Testing: Determines maximum load capacity.

- Ultrasonic or Radiographic Testing: Detects internal voids or cracks.

For safety-critical applications, these tests confirm that the weld meets required codes and specifications.

A lap weld may look simple, but it’s one of the most practical and reliable joints in welding. By overlapping metals and welding their edges, this joint design delivers strong, consistent results with minimal preparation, ideal for everything from car body panels to structural steel.

The welding lap joint combines versatility with efficiency, making it a cornerstone of modern fabrication. Whether you’re working on thin sheet metal or heavy frames, mastering this technique ensures durable, clean, and well-balanced welds that stand the test of time.

FAQs About Lap Joint Welding

Yes, lap joint welding can be very strong—especially when done with the correct overlap distance and welding technique.

The strength largely depends on factors such as metal thickness, weld length, and penetration. A properly executed lap joint often provides shear strength comparable to butt joints for thin-to-medium gauge metals.

In welding, overlap refers to a weld defect where the molten metal extends beyond the weld toe without fusing into the base metal.

It creates a weak edge that can lead to cracks or corrosion. In lap joints, however, “overlap” also describes the intentional overlap distance between two metal pieces—typically 3 to 5 times the metal thickness—to ensure strong bonding.

Yes. Once welded, a lap joint forms a permanent connection between the two metal surfaces.

It cannot be disassembled without cutting or grinding, which makes it suitable for structural, automotive, and fabrication applications that require lasting strength.

Lap joints are considered beginner-friendly because they are simple to align and require minimal edge preparation.

The overlapping surfaces help stabilize the workpieces, making it easier for novice welders to control the weld pool and maintain proper bead shape.

It’s a good joint type for practicing MIG or TIG welding techniques.

To prevent unwanted overlap defects:

1.Control heat input: Excessive current or slow travel speed causes metal to overflow without fusion.

2.Maintain proper torch angle: A 10°–15° push angle ensures smooth bead flow.

3.Use correct filler amount: Avoid excessive filler that spills over edges.

4.Ensure clean base metal: Remove rust, paint, or oil before welding.

5.Follow appropriate travel speed: Keep a consistent pace for even bead penetration.