The welding industry has witnessed radical advances in recent decades, with laser welding technology emerging as a game-changing alternative to conventional welding methods. As manufacturers demand higher precision, faster production rates, and superior weld quality, the debate between laser welding and traditional techniques like TIG, MIG, and stick welding intensifies across various industries.

Laser welding utilizes concentrated light energy to create precise, high-quality welds with minimal heat-affected zones and exceptional accuracy. This advanced technology offers distinct advantages in speed, precision, and application versatility, though traditional methods maintain their relevance in specific scenarios. Understanding the comparative strengths and limitations of each approach helps manufacturers make informed decisions about welding technology investments.

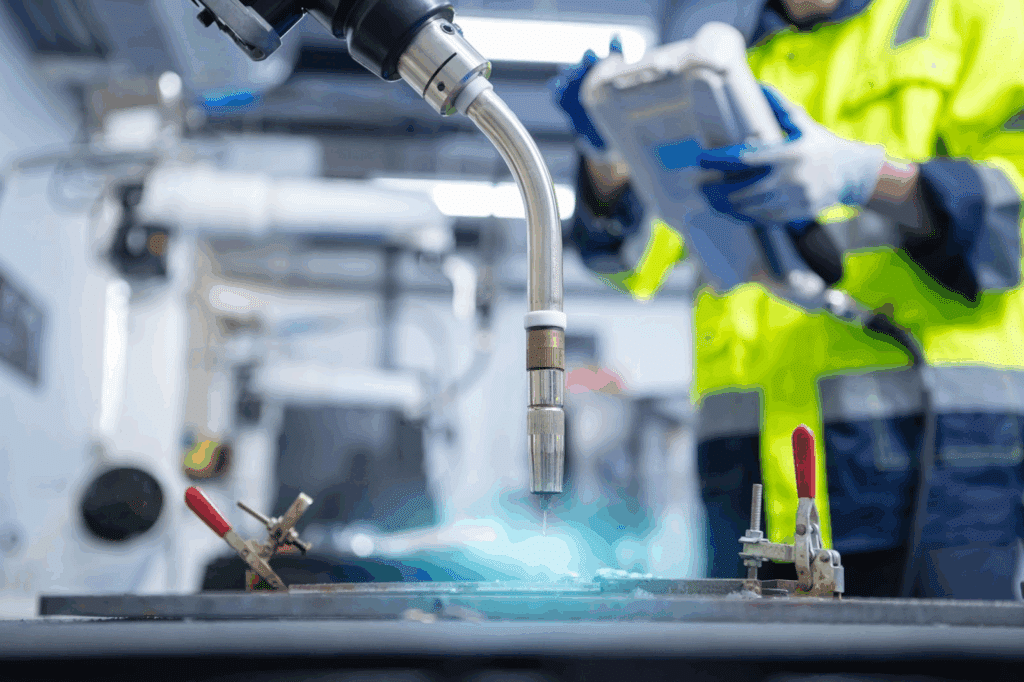

Modern manufacturing environments increasingly prioritize automation, quality consistency, and production efficiency. Laser welding systems address these requirements through computer-controlled precision, repeatable results, and integration capabilities with robotic manufacturing systems. However, traditional welding methods continue evolving with improved consumables, power sources, and automation features that maintain their competitive position in many applications.

Speed Comparison: Production Efficiency Analysis

Laser welding speed represents one of the most compelling advantages over traditional methods, particularly in high-volume production environments. Laser systems can achieve welding speeds up to 10 times faster than conventional TIG welding on similar materials and thicknesses. This dramatic speed increase translates directly into improved productivity and reduced labor costs per unit.

High-speed laser welding operates through concentrated energy density that rapidly melts and fuses materials without requiring extensive preheating or multiple passes. Traditional methods like TIG welding demand careful heat control and often multiple passes for thick sections, significantly extending cycle times. MIG welding offers better speed than TIG, but still cannot match laser welding performance on thin to medium thickness materials.

The speed advantage becomes particularly pronounced in automotive laser welding applications where production volumes demand rapid cycle times. Automotive manufacturers routinely achieve welding speeds exceeding 200 inches per minute using laser systems, compared to 20-50 inches per minute with conventional MIG welding on similar applications.

However, setup and programming time for laser systems can offset speed advantages in short production runs. Traditional methods like stick welding offer immediate setup capabilities that benefit repair work and small-batch production, where programming time cannot be amortized across large quantities. Arc welding vs laser welding comparisons must consider total cycle time, including setup requirements, for accurate productivity assessments.

Laser Welding vs Traditional Methods: Comparison Table

| Feature | Laser Welding | TIG Welding | MIG Welding | Stick Welding |

| Welding Speed | Up to 10 times faster than traditional welding | Slower, especially on thick materials | Faster than TIG, but slower than laser | Slow, suitable for small batch production |

| Precision | Extremely high, as small as 0.1mm | High, but depends on operator’s skill | Medium, suitable for medium-thickness materials | Lower, depends on operator experience |

| Heat-Affected Zone | Very small, reduces distortion and stress | Larger, requires careful heat input control | Smaller, but not as precise as laser welding | Larger, often requiring post-weld correction |

| Material Compatibility | Suitable for a wide range of metals, including thin sheets | Suitable for stainless steel, aluminum, etc. | Suitable for most metals, especially steels | Suitable for thick materials and most metals |

| Thickness Range | From 0.1mm to several inches | Medium to thick materials | Medium thickness, especially for thin sheets | Suitable for thick materials and repairs |

| Equipment Cost | High, starting from $100,000 | Low, around $5,000 – $15,000 | Low, around $5,000 – $10,000 | Lowest, typically under $2,000 |

| Operational Difficulty | High requires specialized training | Medium, relatively simple operation | Medium, requires familiarization with welding techniques | Low, suitable for quick repairs |

Precision and Quality: Accuracy in Weld Characteristics

Precision laser welding delivers unmatched accuracy in weld placement, depth control, and heat input management. Laser beams can be focused to spot sizes as small as 0.1mm, enabling precise welding of delicate components without affecting surrounding areas. This precision level proves impossible with traditional welding methods that inherently produce larger heat-affected zones.

Laser welding accuracy extends beyond physical dimensions to include metallurgical properties. The rapid heating and cooling cycles characteristic of laser welding produce fine-grained microstructures with superior mechanical properties compared to slower traditional welding processes. Minimal heat input reduces distortion and residual stresses that commonly plague conventional welding operations.

Traditional welding methods require skilled operators to maintain consistency, with quality varying based on individual technique and experience. Automated laser welding eliminates human variability through computer-controlled parameters, ensuring identical results across thousands of welds. This consistency proves crucial for applications requiring statistical process control and zero-defect manufacturing.

Penetration control represents another precision advantage for laser welding. Traditional methods often struggle with consistent penetration, particularly on varying joint fits or thickness changes. Laser systems provide precise depth control through beam power and focal position adjustments, accommodating material variations without manual operator adjustments.

Laser beam welding also enables welding in previously inaccessible locations through fiber optic beam delivery systems. Traditional welding torches require direct access and adequate clearance, limiting joint design flexibility and assembly sequence options.

Material Versatility and Thickness Capabilities

Laser welding applications span an impressive range of materials including steel, aluminum, titanium, and exotic alloys. The process excels on thin materials where traditional methods risk burn-through or excessive heat input. Thickness capabilities extend from foils measuring 0.1mm up to several inches in specialized high-power systems.

Aluminum laser welding offers particular advantages over traditional methods that struggle with aluminum’s high thermal conductivity and oxide formation tendencies. Laser welding’s rapid energy input overcomes thermal conductivity challenges while producing clean welds without the porosity issues common in conventional aluminum welding.

Stainless steel applications benefit from laser welding’s minimal heat input, which prevents carbide precipitation and maintains corrosion-resistant properties. Traditional welding often requires special procedures or post-weld treatments to maintain stainless steel performance characteristics.

Traditional methods maintain advantages in very thick sections where laser welding becomes less economical. Heavy structural welding applications favor stick or submerged arc welding methods that can efficiently handle unlimited thickness ranges. TIG vs laser welding comparisons show TIG maintaining superiority for thick-section repair work and applications requiring exceptional cosmetic appearance.

Dissimilar material joining represents an emerging strength for laser welding technology. The precise heat control enables the successful joining of materials with vastly different melting points and thermal properties, applications that prove challenging or impossible with traditional methods.

Heat-Affected Zone and Distortion Control

Laser welding heat input typically measures 10-100 times lower than conventional processes, dramatically reducing heat-affected zone size and associated distortion. This characteristic proves crucial for applications involving heat-sensitive materials or precise dimensional requirements that cannot tolerate welding distortion.

Minimal heat input enables welding of pre-machined components without subsequent dimensional correction, reducing manufacturing costs and improving quality control. Traditional welding often requires post-weld machining or stress relief treatments that add cost and complexity to manufacturing processes.

Laser welding distortion remains minimal even on thin materials prone to warping with conventional methods. Aerospace and electronics industries particularly benefit from this characteristic when welding delicate assemblies that cannot withstand traditional welding heat input levels.

The narrow heat-affected zone also preserves base material properties adjacent to welds, maintaining strength and corrosion resistance characteristics that broader heat input from traditional methods might compromise. This property proves especially valuable when welding heat-treated materials that lose strength through excessive thermal exposure.

Equipment Costs and Economic Considerations

Laser welding equipment requires significantly higher initial investment compared to traditional welding systems. Basic laser welding systems start around $100,000, while comparable MIG or TIG systems cost $5,000-$15,000. This substantial cost difference demands careful economic analysis to justify laser technology adoption.

Operating costs favor laser welding in high-volume applications through reduced labor requirements, faster cycle times, and minimal consumable usage. Laser welding cost analysis often shows payback periods of 1-3 years in production environments with sufficient volume to utilize system capabilities.

Maintenance requirements differ substantially between technologies. Traditional welding equipment uses readily available consumables and can be serviced by in-house technicians. Laser systems require specialized maintenance, expensive consumables like laser tubes or diodes, and often demand service contracts with equipment manufacturers.

Energy consumption comparisons show mixed results depending on application specifics. While laser systems use energy efficiently during welding, overall power requirements including chiller systems and beam delivery components often exceed traditional welding power consumption.

Welding automation costs also favor laser systems in production environments. Traditional welding automation requires complex torch positioning and consumable handling systems, while laser welding automation focuses primarily on part positioning and beam control.

Application-Specific Advantages

Automotive laser welding dominates modern vehicle manufacturing through superior speed and precision for body panel joining, powertrain component assembly, and battery pack welding for electric vehicles. The automotive industry’s volume requirements and quality standards align perfectly with laser welding capabilities.

Electronics laser welding enables miniaturization trends through precise joining of tiny components without heat damage to sensitive electronics. Traditional methods cannot achieve the precision required for modern electronic device manufacturing, particularly for components like battery tabs, sensors, and circuit assemblies.

Medical device manufacturing increasingly relies on laser welding for implant assembly, surgical instrument production, and biocompatible material joining. The cleanliness and precision of laser welding meet stringent medical industry requirements that traditional methods cannot satisfy.

Aerospace applications benefit from laser welding’s ability to join advanced materials like titanium alloys and Inconel without compromising material properties. The reduced heat input preserves heat treatment conditions critical for aerospace component performance.

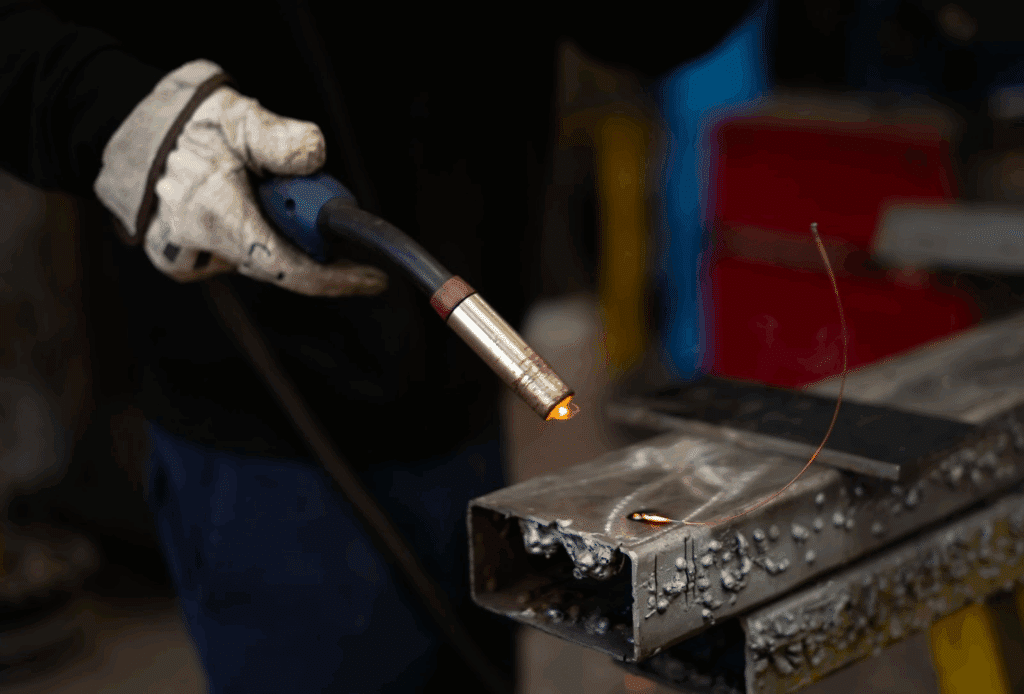

Heavy construction and structural applications continue to favor traditional methods due to thickness requirements, field welding conditions, and economic considerations. MIG vs laser welding comparisons in structural applications consistently favor traditional methods for cost-effectiveness and practical considerations.

Environmental and Safety Considerations

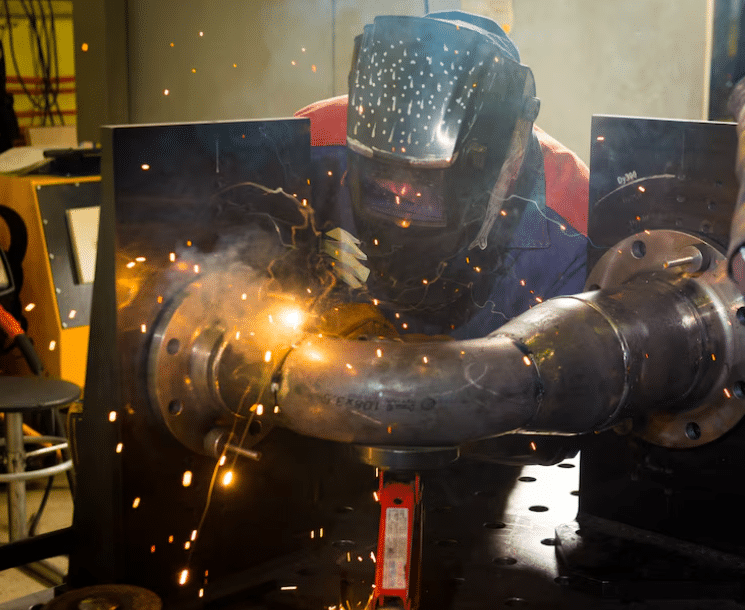

Laser welding safety requires different precautions compared to traditional methods. Laser radiation poses unique eye and skin hazards requiring specialized protective equipment and safety training. However, laser welding produces minimal fumes and spatter compared to traditional methods, improving workplace air quality.

Traditional welding generates significant fumes, UV radiation, and spatter that require ventilation systems and comprehensive personal protective equipment. The visible welding process allows operators to monitor weld quality in real-time, unlike laser welding, which often occurs within enclosed chambers.

Energy efficiency comparisons favor laser welding for actual welding time, though total system energy consumption, including auxiliaries, may exceed traditional methods. Environmental impact assessments must consider equipment manufacturing, consumable usage, and end-of-life disposal requirements.

Future Technology Trends

Laser welding technology continues to advance through improved beam quality, higher power levels, and enhanced automation integration. Fiber laser development has reduced equipment costs while improving reliability and maintenance requirements, making laser welding accessible to smaller manufacturers.

Traditional welding technology also evolves through improved power sources, enhanced automation capabilities, and better consumable materials. Digital welding systems now offer many automation benefits previously exclusive to laser welding, narrowing the capability gap in some applications.

Hybrid welding processes combining laser and traditional methods emerge as promising technologies that leverage the advantages of both approaches. These systems offer potential solutions for applications where neither technology alone provides optimal results.

The choice between laser welding and traditional methods depends on specific application requirements, production volumes, and economic considerations. Laser welding excels in high-volume production requiring precision and speed, while traditional methods remain superior for thick sections, field work, and cost-sensitive applications.

Understanding the comparative advantages helps manufacturers select appropriate welding technology for their specific needs. As laser welding costs continue decreasing and traditional methods advance through automation, the competitive landscape continues evolving.

For comprehensive welding solutions spanning both traditional and advanced technologies, explore the professional equipment available at YesWelder. Their expertise can help evaluate which welding approach best serves your specific manufacturing requirements and budget considerations.