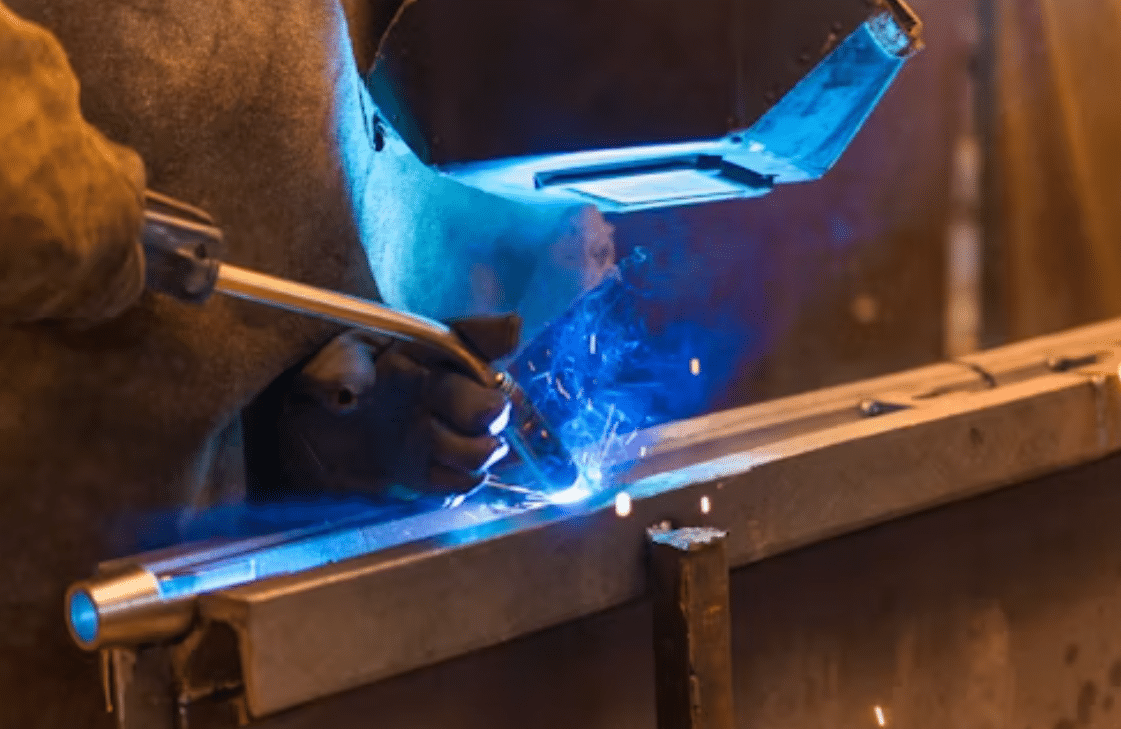

Welding 304 Stainless Steel: How to Achieve Corrosion-Resistant Welds

304 stainless steel is incredibly common. You see it in restaurants, food-processing lines, handrails, marine hardware, and brewery tanks. It’s durable, rust-resistant, and easy to form. And yes, it welds well too, but only if you control the heat and avoid contamination. In this guide, you’ll learn the best welding