GTAW Welding Equipment: The Complete Guide to Tools and Setup

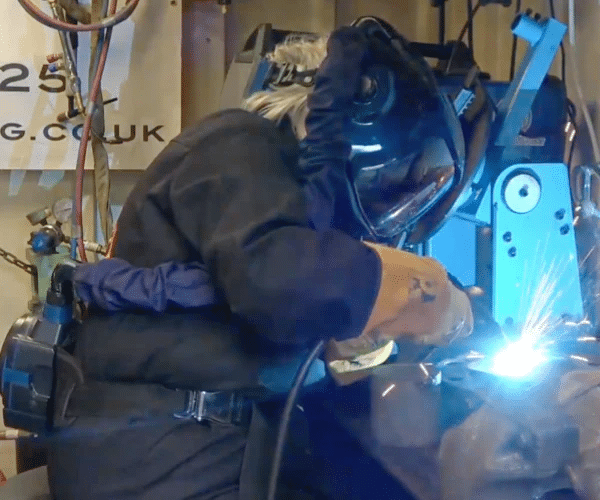

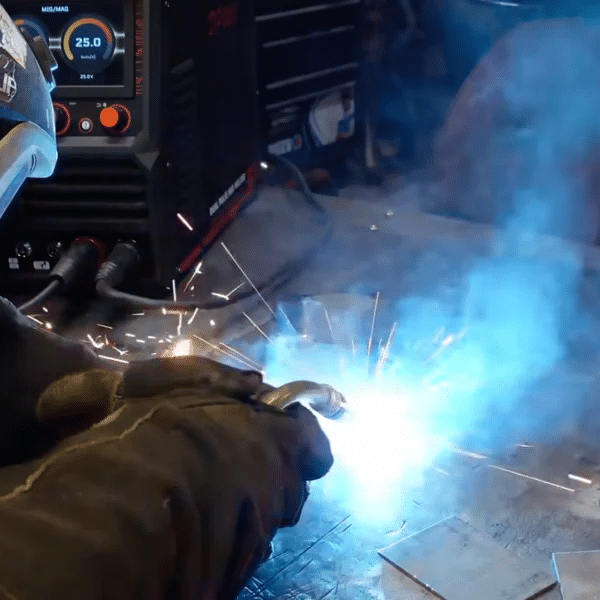

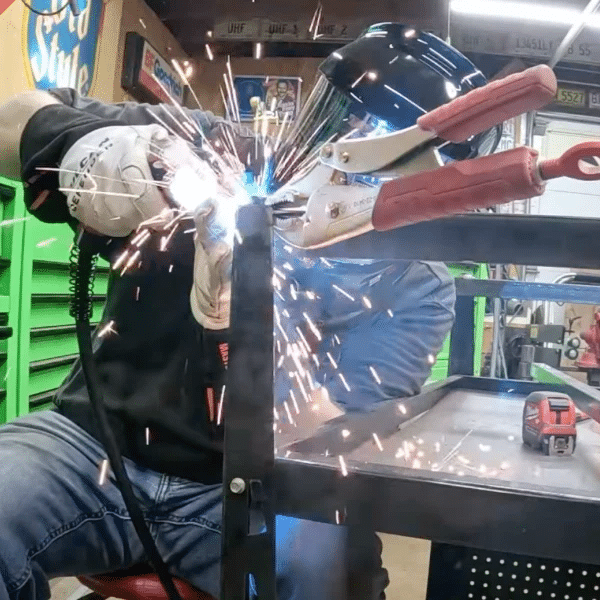

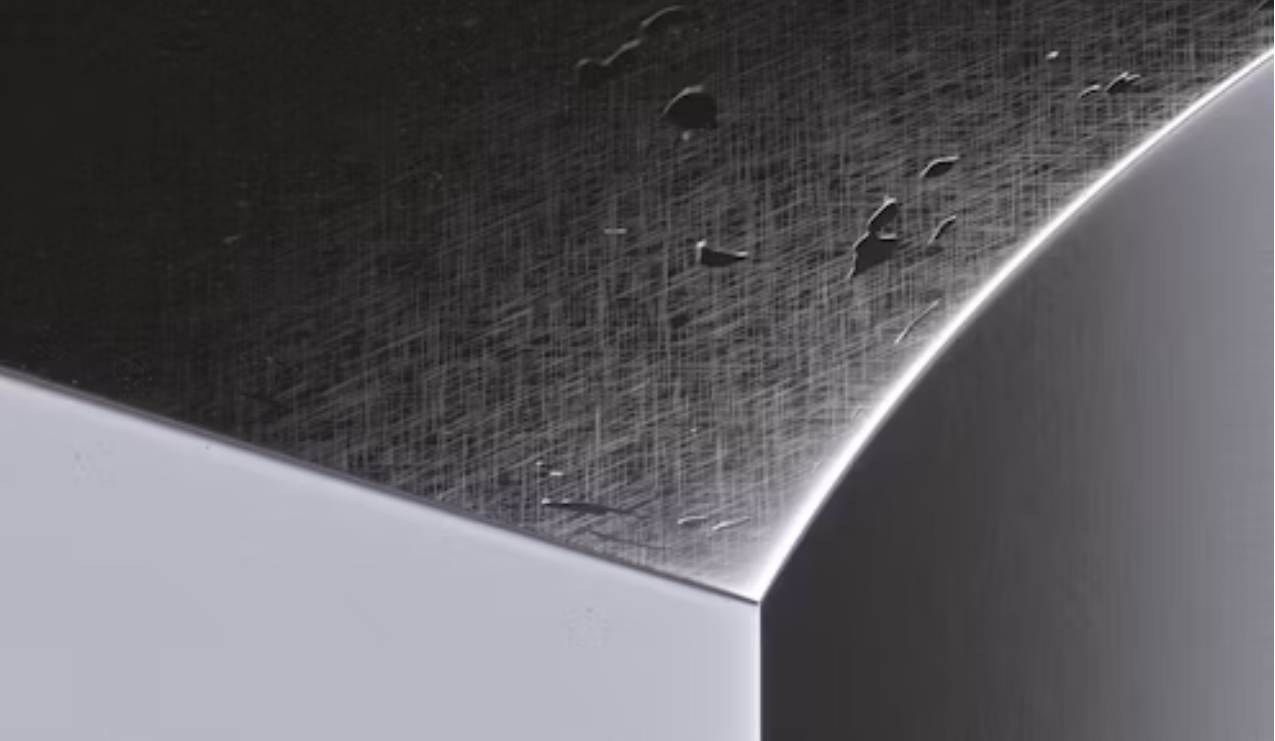

If you’re aiming for precision, beauty, and strength in your welds, few methods can match GTAW welding, better known as TIG welding (Tungsten Inert Gas welding). It’s the process of choice for professionals who need clean, high-quality welds on stainless steel, aluminum, and exotic metals. But mastering GTAW starts with