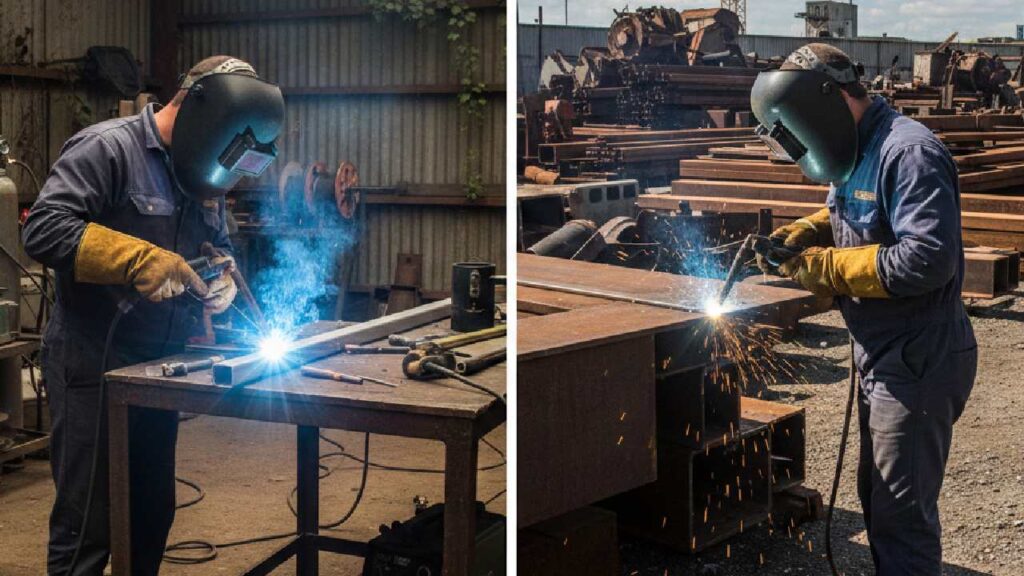

TIG welding and arc welding both create strong metal joints, but they are designed for very different kinds of work.

TIG welding focuses on precision, clean appearance, and tight heat control. Arc welding (often called stick welding) focuses on strength, speed, and reliability in rough conditions. Neither method is universally better. The right choice depends on your material, work environment, experience level, and budget.

In this guide, we compare TIG welding vs arc welding across weld quality, performance, learning curve, operating cost, and real-world applications to help you choose the process that actually fits your job.

What Is TIG Welding?

TIG welding is a precision welding process that uses a non-consumable tungsten electrode and external shielding gas to produce clean, controlled welds.

Because heat input and filler metal are controlled separately, TIG welding allows excellent accuracy and a consistent bead appearance. This makes it ideal for thin materials and projects where weld appearance matters.

Key characteristics of TIG welding include:

- Non-Consumable Tungsten Electrode

- External Shielding Gas (Usually Argon)

- Minimal Spatter And Slag

- Precise Heat And Puddle Control

TIG welding is commonly used when accuracy, consistency, and visual quality are top priorities.

What Is Arc Welding?

Arc welding is a manual welding process that uses a flux-coated consumable electrode to create strong, deeply penetrated welds.

The flux coating produces its own shielding gas, which allows arc welding to work reliably outdoors and on imperfect or contaminated surfaces. This process is widely used for structural and repair work.

Key characteristics of arc welding include:

- Consumable Flux-Coated Electrode

- Self-Shielding Arc

- Deep Penetration And High Strength

- Simple Setup And Excellent Portability

Arc welding is known for its durability and reliability in demanding environments.

How Does TIG Welding Compare to Arc Welding at a Glance?

This comparison table highlights the most practical differences between TIG welding and arc welding, especially for beginners and first-time buyers.

| Feature | TIG Welding | Arc Welding |

| Weld Appearance | Clean And Visually Smooth | Strong But Rougher |

| Material Thickness | Thin To Medium | Medium To Thick |

| Welding Speed | Slower | Faster |

| Equipment Complexity | High | Low |

| Portability | Limited | High |

| Skill Requirement | Advanced | Beginner-Friendly |

| Operating Cost | Higher | Lower |

Which Produces Better Weld Quality: TIG or Arc Welding?

TIG and arc welding both produce high-quality welds, but they define quality in different ways.

TIG welding emphasizes control and appearance. It produces smooth, consistent bead profiles with minimal cleanup, which matters when welds are visible or when materials are thin.

Arc welding emphasizes penetration and joint strength. It delivers reliable results on thick steel and tolerates surface contamination such as rust or paint.

TIG welding delivers better results when precision and appearance matter:

- Clean Bead Profiles

- Minimal Post-Weld Cleanup

- Strong Fusion On Thin Metals

- Visually Consistent Welds

Arc welding performs better when strength and penetration are the priority:

- Deep Penetration

- High Structural Strength

- Reliable Performance On Dirty Surfaces

- Thick Material Welding

Which Is Easier to Learn: TIG Welding or Arc Welding?

Arc welding is easier to learn than TIG welding for most beginners.

TIG welding requires coordinated control of torch angle, filler rod feeding, and heat input, often using both hands and a foot pedal. Mastery takes time and steady practice.

Arc welding uses simpler motions and techniques. Once basic arc striking and electrode handling are learned, new welders can produce usable welds quickly.

If ease of learning matters more than weld appearance, arc welding is the simpler choice.

Which Welding Process Is Faster and More Productive?

Arc welding is faster and more productive for heavy-duty work.

The consumable electrode melts continuously, allowing faster deposition with fewer pauses. This makes arc welding well-suited for thick steel and large joints.

TIG welding is slower because filler metal is added manually and heat is carefully controlled. While this reduces speed, it improves accuracy and weld consistency.

For high-volume or thick steel work, arc welding saves time. For detailed or cosmetic welds, TIG welding trades speed for precision.

How Do Equipment Setup and Portability Differ?

Arc welding offers a simpler and more portable setup than TIG welding.

TIG welding requires a power source, torch, shielding gas cylinder, regulator, and often a foot pedal. This increases cost and limits portability, especially outdoors.

Arc welding typically requires only a power source, electrode holder, ground clamp, and rods. Many arc welders are lightweight and easy to move between job sites.

How Do Operating Costs Compare Over Time?

Arc welding has lower upfront and long-term operating costs.

Equipment is affordable, consumables are inexpensive, and no external shielding gas is required. Maintenance costs are also lower.

TIG welding involves higher costs due to machine price, shielding gas usage, tungsten electrodes, and the need for skilled operation. These costs are often justified for precision or cosmetic work.

Where Are TIG and Arc Welding Used in Real-World Applications?

TIG welding is commonly used in applications that require clean, precise welds:

- Aerospace Components

- Stainless Steel And Aluminum Fabrication

- Automotive Exhaust Systems

- Medical And Food-Grade Equipment

Arc welding is commonly used in heavy-duty and outdoor applications:

- Construction And Structural Steel

- Pipeline Installation And Repair

- Heavy Equipment Maintenance

- Outdoor And Emergency Welding

When Should You Choose TIG Welding vs Arc Welding?

Choose TIG welding if:

- Weld appearance matters

- You work with thin or heat-sensitive metals

- Precision and control are critical

Choose arc welding if:

- Strength matters more than appearance

- You weld thick or contaminated materials

- Portability and lower cost are priorities

Conclusion

TIG welding and arc welding are both proven processes when used in the right situations.

TIG welding delivers precision, control, and clean welds for detailed and cosmetic work. Arc welding provides strength, speed, and reliability for demanding environments and heavy materials.

If you’re deciding which process fits your next project, start with one simple question: Does this job require precision or toughness? That answer usually points you in the right direction.

If you’re ready to upgrade your setup, YesWelder offers a full range of TIG and arc welders designed for real-world welding—from home workshops to job sites.

FAQs

The rule of 33 in TIG welding is a guideline that suggests using about 33 amps per 1/16 inch of material thickness. For example, welding 1/8-inch steel typically requires around 125 amps. This rule helps beginners set a safe starting point, but fine adjustments are often needed based on joint design and heat control.

The main disadvantage of TIG welding is its slow speed and steep learning curve.

TIG welding also costs more to operate due to shielding gas, tungsten electrodes, and higher equipment prices. For thick steel or high-volume work, other processes are usually more efficient.

MIG welding is much easier to learn than TIG welding. MIG uses a continuous wire feed and simpler hand movements, allowing beginners to make acceptable welds quickly. TIG welding requires precise coordination of heat, torch angle, and filler metal, which takes significantly more practice.

Most beginners should start with a MIG or stick welder. MIG welding is ideal for clean indoor projects and thin metal, while stick welding works well outdoors and on thicker or rusty steel. TIG welding is better learned after gaining basic welding experience.

TIG welding is best suited for thin metals and non-ferrous materials, especially aluminum and stainless steel.

It is also commonly used on magnesium, titanium, and chromoly steel, where clean, precise welds and tight heat control are required.

TIG welders are more expensive because they require advanced power control, stable arc output, and additional components such as gas regulation and foot pedals.

These features allow precise heat adjustment, but they also increase manufacturing cost and overall system complexity.