Controlling the welding flame ensures a quality weld without losing sight of the welder’s safety and material. Every color of a welding flame says important information about flame temperature, composition, and their likely action on the metals. All the information is a guide towards preventing welding defects and strengthening joints.

The Importance of Flame Control in Welding

In welding, flame control improves the weld quality and efficiency. A correct flame would provide a constant heat source, improving the conditions of the welded metal and avoiding unwanted oxidation or carbon buildup.

Proper flame control enables the welders to work with temperature. It will not contaminate the metal and develop strength and durability in the weld.

Without proper flame control, welds result in poor quality. A wrong adjustment may present weak joints, porosity, and cracks in joined metals since such imperfections compromise the welded material structural integrity.

Understanding the various types of flames and colors will ensure the proper heat application, prevent damage, and optimize productivity.

Types of Welding Flames

There are three major types of flames: neutral, carburizing, and oxidizing flames. Each type of welding flame has different characteristics, making it suitable for a specific welding requirement.

Neutral Flame

This is the most common type of welding flame and is usually used for general-purpose welding. It has a balanced ratio between oxygen and fuel.

The temperature is moderate for this flame. Hence, there is no oxidation or carbon deposit on the surface of the welded part.

Carburizing (Reducing) Flame

This flame has additional fuel, creating a reducing atmosphere ideal for metals easy to oxidize. It has a cooler temperature, which is ideal for metals like high-carbon steel or cast iron.

Oxidizing Flame

This flame has excess oxygen and burns even hotter than the other flames, making it great for cutting or welding copper alloys.

However, it risks an oxidized layer on the metal surface, which forms a weakened area in welds in some metals.

What Do Flame Colors Indicate

The color of the welding flame shows its chemical composition, temperature, and suitability for certain welding tasks. The right color of a welding torch flame enhances the quality of a weld while the wrong color may signal problems.

Blue: This usually tells a neutral or carburizing flame. It is good for general welding.

White or Yellowish White: An oxidizing flame is usually hotter and can be destructive if not treated with care.

Orange or Yellow: The carburizing (reducing) flame is the one with more carbon and is best suited for metals requiring a reducing atmosphere.

Being able to understand flame color and type will enable the welder to adjust the flame according to the metal type. It also provides strength to the weld while minimizing the probability of imperfections.

Neutral Flame and Color

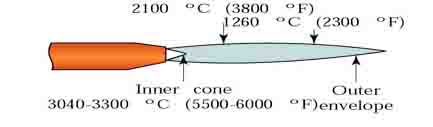

The neutral flame has the most balanced and widest application in welding. The flame color is represented by a clear, bright blue cone surrounded by an inconspicuous outer envelope. This flame will have roughly equal proportions of oxygen and fuel gas. It is used for most general welding tasks, such as welding steel.

Characteristics of a Neutral Flame

| Aspects | Neutral Flame Characteristics |

| Temperature | About 3,200°C (5,792°F) |

| Application | Suitable for metal that does not need additional carbon or oxygen (e.g. mild steel, stainless steel, and aluminum.) |

| Effect on Weld | Have minimum oxidation, yielding clean and solid welds free from surface impurities |

Carburizing Flame and Color

The carburizing, or reducing, flame has an excess of fuel. It has a lower temperature compared to the neutral flame. It has a feather-like, blue inner cone with a secondary, luminous feather extending from the primary cone.

Characteristics of a Carburizing Flame

| Aspects | Carburizing Flame Characteristics |

| Temperature | About 3,000°C (5,432°F) |

| Application | Good for high-carbon steel, cast iron, and other metals benefit from carbon enrichment |

| Effect on Weld | Unites carbon into the weld |

Oxidizing Flame and Color

An oxidizing flame has more oxygen than fuel. The flame is hotter and more intense. Its color is a short, intense, bluish-white inner cone surrounded by a barely visible outer envelope. The oxidizing flame is used cautiously because it risks adding unwanted oxygen to the weld.

Characteristics of an Oxidizing Flame

| Aspects | Oxidizing Flame Characteristics |

| Temperature | Around 3,500°C (6,332°F) |

| Application | Suitable for cutting, brazing, and manipulation of copper alloys |

| Effect on Weld | Give an oxidized weld surface, making the weld brittle and less strong if not appropriately controlled |

Difference Between Each Welding Flame and Color

The major differences between the welding flames are based on the oxygen-to-fuel ratio, the temperature, and the influence on metal properties.

| Flame Types | Main Differences |

| Neutral Flame | Fuel=Oxygen; Balanced, versatile, and produces less oxidation. |

| Carburizing Flame | Fuel>Oxygen; Lower temperature, enriches metal with carbon, good for high-carbon steel. |

| Oxidizing Flame | Fuel<Oxygen; Hottest flame, can cause oxidation; Primarily used for cutting |

Each of these flame types has its specific advantages and limitations, which will depend on the material being welded and on the quality of the weld one wants to achieve.

For most applications, a neutral flame will yield the most uniform results. The carburizing and oxidizing flames allow for more specialized welding tasks.

Flame Adjustment Techniques

Mastering flame adjustment is to achieve the result one needs from welding. Here are tips for adjusting fuel-to-oxygen ratios effectively.

1. Set the Acetylene: Open the acetylene valve slightly and ignite it. Then adjust it to where only minimal soot is experienced.

2. Add Oxygen Gradually: Open the oxygen valve slowly to adjust the flame from yellow to blue.

Achieve the Desired Flame Type

Neutral Flame: Adjust the inner cone until it is sharp, blue, and feather-free.

Carburizing Flame: The flame is adjusted by reducing the oxygen supply, which results in a feathered inner cone.

Oxidizing Flame: Increase oxygen slightly until the flame shortens and the inner cone becomes bright white.

Routine adjustments will help maintain the flame, reducing weld contamination and assuring a clean and effective weld.

Safety Considerations in Welding Flame

The first basic factor in assuring safety as well as welding quality is developing flame color awareness!

1. Identify the Correct Flame Color: The proper flame color does not allow defects such as too much oxidation, carbonization, and poor weld strength.

2. Oxidizing Flames: Since the oxidizing flames burn much hotter, they tend to depreciate metal surfaces. This will need special care when dealing with materials that easily oxidate, and their observation is done to avoid defects.

3. Equipment Care: Inspect periodically for the condition of torches, gauges, and hoses to avoid flame instability and gas leakage.

Final Thoughts

Being able to identify and adjust the welding flames and their color is a basic expertise in the performance of quality, defect-free welds.

By understanding the flame types and what the colors mean, welders will be able to reach better quality in their work. With flam color awareness, welders can also minimize unnecessary material damage. Recognizing these features, applying proper techniques, and using quality machines from reliable welding machine suppliers, the weld safety, efficiency, and durability are easier to get.

FAQ

What does a blue flame indicate in welding?

A blue color generally indicates a neutral or balanced carburizing flame. It fits standard welding.

How can I prevent oxidation in welding?

Neutral or slightly carburizing flames are ideal because they restrict the amount of excess oxygen that could lead to brittle welds.

Why is flame adjustment necessary?

Flame adjustment is important. It will manage temperature, and at the same time, avoid oxidation or carbon buildup to ensure the weld strength.

What is the hottest type of welding flame?

The oxidizing flame contains more oxygen than fuel and is the hottest. This flame, in general, should be used for cutting or brazing. However, welders should be careful to handle it with proper PPE from professional welding helmet suppliers.