What Is Oxy Fuel Welding

Oxy-fuel welding is a process that mixes a fuel gas, like acetylene or propane, with oxygen to produce a flame hot enough to weld or cut metals. This portable, precise technique powers everything from DIY repairs to professional pipelines and artistic sculptures.

Keep reading and unpacking the oxy fuel welding—for beginners and pros to spark their next project! You can also learn more about different types of welding from our blog articles.

History of Oxy-Fuel Welding

To more fully appreciate oxy-fuel welding, it’s better to understand its history. The process was invented in 1903 by French engineers Edmond Fouché and Charles Picard. Their experimentation was with the controlled combustion of a fuel gas and oxygen, and their initial work was focused on acetylene due to its ability to produce high flame temperatures.

The early 20th century witnessed the extensive use of oxy-fuel welding in a variety of industries. It was a staple in shipbuilding by the 1910s as a versatile and relatively portable method of joining large metal structures.

The roaring twenties witnessed extensive use in auto repairs, where mechanics employed it to fix damaged automobile bodies and parts. Its importance peaked during World War II, where it was critically utilized in manufacturing everything from aircraft parts to military equipment.

While arc welding of MIG welders and TIG welding machines have gained popularity (Click here to know what is arc welding), oxy-fuel welding has not remained stagnant.

The 2020s have seen a solid trend towards alternative, cleaner-burning fuel gases like propane and hydrogen. Moreover, torch design improvements have led to both more efficient and safer equipment.

How Does Oxy-Fuel Welding Work?

Oxy-fuel welding relies on a simple but powerful principle at its core: the combustion of a fuel gas in oxygen to create an extremely hot flame.

When the fuel being used is acetylene, the resulting flame is approximately 3,773 Kelvin (6,332 degrees Fahrenheit), which is hot enough to melt most common metals.

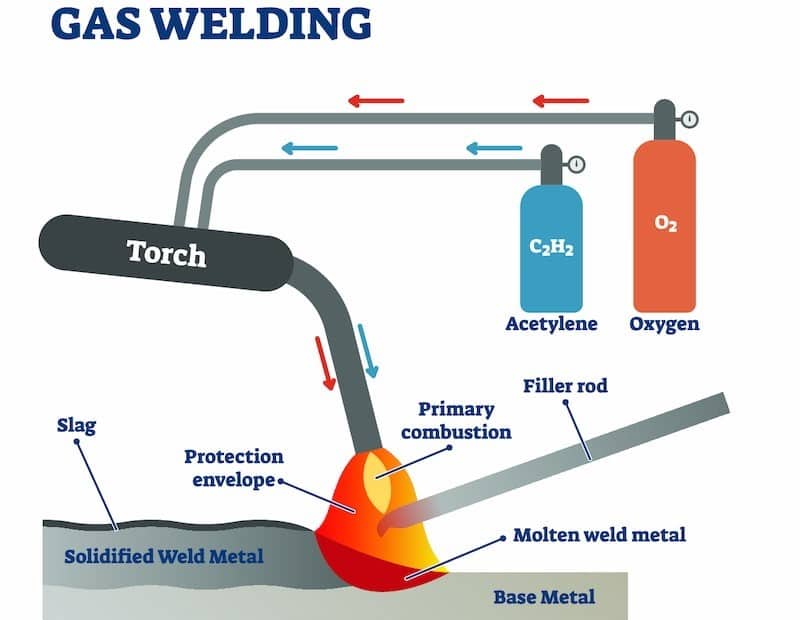

The typical oxy-fuel welding setup consists of several key components:

- Torch: The handheld device where the fuel gas and oxygen are mixed and ignited.

- Regulators: Attached to the gas cylinders, these control the pressure of the gases reaching the torch.

- Hoses: Flexible tubes that carry the gases from the cylinders to the torch.

- Gas Cylinders: High-pressure containers holding the fuel gas (commonly acetylene, but also propane or MAPP gas) and oxygen.

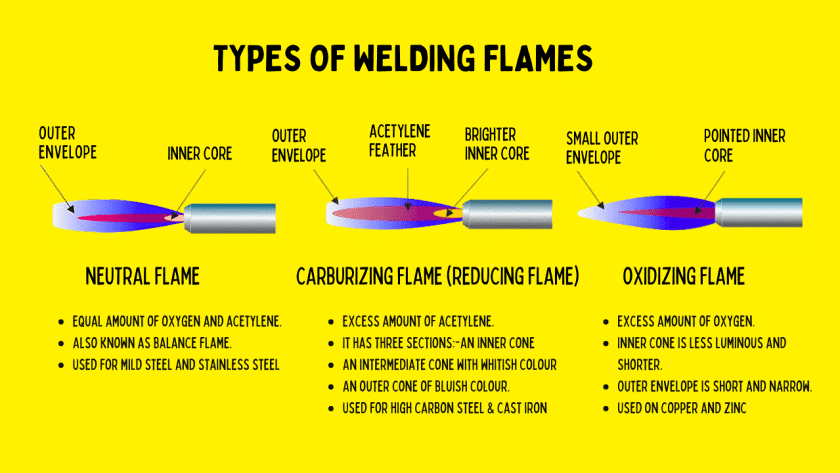

The welder controls the flame characteristics by adjusting the fuel gas and oxygen proportion. There are three broad categories of welding flames most commonly used.

- Neutral Flame: A balanced fuel and oxygen proportion flame and most commonly used for welding steel, stainless steel, copper, and aluminum.

- Oxidizing Flame: This is a hotter flame than the neutral flame, with an excess of oxygen, and is used predominantly for welding bronze and brass.

- Reducing (or Carburizing) Flame: This flame has an excess of fuel gas and is characterized by three distinct flame zones. It’s often used for welding high-carbon steels and some non-ferrous metals.

How to Oxy Fuel Weld

Step 1: Assemble the Equipment

Ensure you have a complete oxy-fuel welding setup. This includes the torch, acetylene and oxygen cylinders, regulators, hoses, and required Personal Protective Equipment (PPE) such as welding gloves, a welding helmet with a shade 5 or higher lens, and a flame-resistant jacket.

Step 2: Set Up Safely

Inspect all equipment carefully for leaks or damage before you start. Hold the gas cylinders securely upright so that they won’t fall. Make sure your work area is well ventilated and away from flammable materials.

Step 3: Adjust the Regulators

Add the regulators slowly to the correct cylinders. For welding mild steel, a common starting point would be around 5 psi for acetylene and 20 psi for oxygen. Refer to manufacturer instructions for specific material and torch tip size.

Step 4: Light and Adjust the Flame

Open the acetylene valve on the torch ever so slightly and light the gas with a striker. Slowly increase the amount of acetylene flow to a smoky flame that emits from the tip. Then, slowly open the oxygen valve and tinker with adjusting the mixture to get a neutral flame – having a distinctly well-defined bright white inner cone.

Step 5: Begin Welding

Keep the workpiece secure. Position the torch at a 45-degree angle to the metal surface and direct the neutral flame to the starting point.

As the metal starts heating and forming a molten puddle, you can introduce a filler rod (if needed) into the puddle at a small angle. Travel the torch in a normal sequence (for example, circular or side-to-side) to create a weld bead.

Troubleshooting Common Issues

1. Popping Flame: This usually results from over-heating the torch tip or holding the tip too close to the work. Let the tip cool or alter your method.

2. Weak Weld: A weak weld could be the result of lack of heat, incorrect filler rod method, or dirty metal surfaces. Clean appropriately and alter your flame and technique accordingly.

Oxy Fuel Welding Applications

The flexibility of oxy-fuel welding is such that it can be used for a wide range of work. In the United States, oxy-fuel welding plays a critical role in the maintenance of the extensive oil and gas pipeline infrastructure, particularly in states like Texas and Oklahoma.

There are more types of oxy fuel welding applications:

- Industrial: Oxy-fuel welding is still used extensively for repairing pipelines, especially in remote locations without continuous electricity. It is also employed in ship repair as well as the repair of heavy machinery.

- Automotive: As old cars are restored to fixing exhaust systems, oxy-fuel welding is an age-old craft in the transportation sector.

- Artwork: Many metal sculptors utilize the precise control offered by oxy-fuel welding to create intricate and beautiful works of art, including kinetic wind art that has seen a surge in popularity in 2025.

- DIY Projects: Homeowners may employ oxy-fuel welding in repairing all types of equipment, such as gates, fences, and other metal equipment within the premises. Propane is preferable to acetylene in DIY due to its low cost and suitability for handling.

- New Applications: New developments are expanding the areas of application of oxy-fuel welding. Micro-welding in delicate electronic components and eco-friendly projects involving hydrogen as a green fuel source are gaining popularity.

5 Tips of Oxy-Fuel Welding Safety

Safety first when working with oxy-fuel welding equipment. Know the hazards and use proper precautions to make the perfect outcome.

- Hazards: Understand the hazards of flashbacks (where the flame burns backward into the torch and perhaps the cylinders), acetylene instability at pressures above 207 kilopascals (30 psi), and the risk of UV burns from the intense flame.

- PPE: Use the right Personal Protective Equipment (PPE) at all times, including a welding helmet with a lens of shade 5 or higher to protect your eyes from the bright light and any sparks, heavy leather welding gloves to protect your hands from heat and burns, safety glasses under the helmet for additional protection, and a flame-resistant jacket and pants.

- Setup Safety: Store gas cylinders upright and secure them to prevent falling over. Always use flashback arrestors on the torch and regulators to prevent the backflow of gas. Ventilate your workspace to prevent the inhalation of fumes.

- Emergency Tips: Know how to handle cylinder leaks – typically by taking the cylinder to a safe, open area and notifying the supplier. Keep a Class B fire extinguisher nearby in case of fire.

Oxy-Fuel Welding vs. Other Welding Methods

Oxy-fuel welding often proves ideal for off-grid farms or ranches where portability is key for equipment repairs. Choosing the right welding method depends on the specific application. Here’s a comparison to help you understand where oxy-fuel welding excels.

| Feature | Oxy-Fuel Welding | MIG Welding | TIG Welding |

| Portability | Excellent (no electricity needed) | Good (requires a power source) | Fair (requires a power source and shielding gas) |

| Speed | Moderate | Fast | Slow (precise, often for thinner materials) |

| Precision | Good (requires skilled hand-eye coordination) | Fair | Excellent (highly controllable) |

| Versatility | High (welding, cutting, heating, brazing) | Good (primarily for welding) | Good (welding various metals) |

| Materials | Steel, stainless steel, aluminum (with flux), etc. | Steel, stainless steel, aluminum | Steel, stainless steel, aluminum, copper, etc. |

| Cost (Setup) | ~$500 (torch, regulators, cylinders) | ~$1,000+ (welder, gas cylinder) | ~$1,500+ (welder, shielding gas cylinder) |

| Pros | Portable, versatile, lower initial cost | Fast, relatively easy to learn | High-quality welds, precise control |

| Applications | Remote repairs, fabrication, art, heating | Production welding, auto body repair | High-quality welds on thin materials, aerospace |

Get Started with Oxy-Fuel Welding Today

Oxy-fuel welding is a testament to the enduring vitality of fundamental engineering principles. Its versatility, relative cost-effectiveness, and that it doesn’t need electricity make it a key skill for lots of projects

Ready to ignite your passion for metalworking? Here are your next steps:

- Explore Starter Kits: Research and consider purchasing a starter oxy-fuel welding kit designed for beginners from a reputable supplier. Choose kits including essential safety gear. YesWelder wholesale is a trusted supplier of welding PPE, welding consumables as well as types of welding machines.

- Take a Welding Class: On-site instruction by a seasoned instructor is worth its weight in gold to learn techniques and safety protocols. Look for courses in welding at local community colleges or vocational schools.

- Watch Tutorials: Continue with online video tutorials from experienced welders for further instructions.

FAQs About Oxy-Fuel Welding

What’s the hottest oxy-fuel flame?

The hottest oxy-fuel flame occurs by using acetylene and oxygen, which is around 6,332°F (3,773 K).

Can oxy-fuel welding aluminum?

Yes, oxy-fuel can weld aluminum, but sometimes it takes a special flux to prevent oxidation. It also needs more skill than welding steel.

Is oxy-fuel welding safe for beginners?

Yes, oxy-fuel welding can be safe for new users if they are properly trained, aware of the hazards, and consistently adhere to safety protocols.

How much does oxy-fuel equipment cost?

Typically, a starter kit for oxy-fuel welding (which has a torch, regulators, and hoses) often will cost anything from $300 to $700, not including the purchase of the gas cylinders themselves.