When it comes to welding, not all joints are created equal. Some are designed for beauty and precision, others for raw strength and endurance. Whether you’re building a bridge, fabricating a pressure vessel, or repairing heavy equipment, the question every welder eventually asks is: What is the strongest weld?

The answer depends on several factors, including the welding method, joint design, materials used, and the welder’s skill. But when it comes purely to strength and structural integrity, a few welding processes consistently stand above the rest.

This guide breaks down the strongest type of weld, the science behind what makes a weld strong, and how to ensure your welds stand up to stress, impact, and time.

What Is the Strongest Type of Weld?

While several methods produce strong joints, TIG (GTAW) and Submerged Arc Welding (SAW) are often considered the strongest type of weld.

- TIG Welding offers the cleanest, most precise, and defect-free joints, making it the top choice for critical or high-performance applications.

- Submerged Arc Welding, on the other hand, dominates in large-scale industrial fabrication where strength and efficiency are paramount.

Ultimately, the “strongest” depends on context: TIG excels in precision, while SAW rules in mass structural strength.

What Determines Weld Strength?

Before diving into specific processes, it’s important to understand what makes one weld stronger than another. Several variables contribute to the final strength of a weld joint:

1. Welding Process

Each welding method has different penetration levels, filler material usage, and heat input, all of which affect bond strength.

2. Joint Design

The geometry of the joint, such as butt, fillet, or groove, determines how forces are distributed across the weld.

3. Material Compatibility

Strong welds require compatible base and filler metals. Mismatched materials can create brittle or porous joints.

4. Heat Control

Too much heat can weaken the surrounding metal (the heat-affected zone), while too little prevents full fusion.

5. Skill Level

Even the strongest welding method fails if technique, speed, or electrode angles aren’t properly controlled.

Ranking the Strongest Welding Processes

Different welding techniques excel in various situations. However, when considering overall tensile strength, fusion depth, and reliability, these methods come out on top.

1. TIG Welding (GTAW – Gas Tungsten Arc Welding)

Why It’s Strong:

TIG welder produces precise, high-quality welds with exceptional strength and minimal spatter. The process uses a non-consumable tungsten electrode and a shielding gas (usually argon) to create a clean, controlled weld pool.

TIG welds are extremely dense and free from impurities, making them ideal for applications where strength and appearance both matter, like aerospace, nuclear, and piping systems.

Advantages:

- Clean, defect-free welds.

- Excellent control over heat and filler addition.

- Superior strength-to-weight ratio.

- Works on almost all metals, including stainless steel, titanium, and aluminum.

Best For:

Critical joints, thin metals, and high-strength applications requiring precision and durability.

Limitation:

TIG welding is slower and requires high skill, which can limit production speed.

Further Reading: Want to master the equipment behind TIG welding? Check out our full guide — GTAW Welding Equipment: The Complete Guide to Tools and Setup to understand every component from the power source to shielding gas systems.

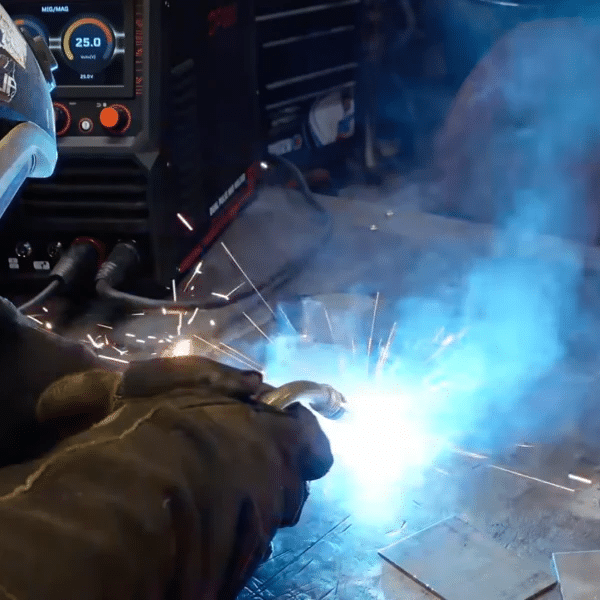

2. MIG Welding (GMAW – Gas Metal Arc Welding)

Why It’s Strong:

MIG welder offers deep penetration and consistent results, especially when using a mixture of argon and CO₂ shielding gases. The continuous wire feed ensures strong, uniform welds suitable for both thin and thick materials.

With proper settings and technique, MIG welds can rival TIG in strength, particularly in structural and industrial environments.

Advantages:

- High deposition rate (faster welds).

- Deep penetration and strong joints.

- Easy to learn and highly productive.

Best For:

Automotive frames, construction, and manufacturing.

Limitation:

Slightly more prone to spatter and porosity if not shielded properly.

Further Reading: Learn more about GMAW welding in our related article — What Does GMAW Stand For? Understanding Gas Metal Arc Welding for a deeper look at how MIG welders deliver speed and precision.

3. Stick Welding (SMAW – Shielded Metal Arc Welding)

Why It’s Strong:

Stick welder is the go-to method for heavy-duty structural work. It delivers deep fusion and strong joints, even in harsh outdoor conditions. The flux-coated electrode provides its own shielding, protecting the weld pool from contamination.

It’s widely used in pipeline, shipbuilding, and heavy construction, where weld strength is critical.

Advantages:

- Excellent penetration and fusion.

- Works on rusty or dirty metals.

- Ideal for outdoor and all-position welding.

Best For:

Bridges, ship hulls, oil rigs, and thick plate steel.

Limitation:

Rougher finish compared to TIG or MIG; requires post-weld cleaning.

Further Reading: Want to learn more about where stick welding truly excels? Check out our in-depth guide — All About Stick Welding Applications: Pros and Cons — to explore its real-world uses, advantages, and limitations.

4. Flux-Cored Arc Welding (FCAW)

Why It’s Strong:

Flux-cored welding combines the productivity of MIG with the penetration of stick. It uses a flux-filled wire, which provides additional shielding and allows deeper fusion.

Self-shielded versions are ideal for high-wind or outdoor applications where gas shielding would fail.

Advantages:

- Excellent for thick materials.

- High deposition rates for heavy fabrication.

- Strong, durable joints even in challenging environments.

Best For:

Structural steel, pipelines, shipyards, and heavy equipment fabrication.

Limitation:

More spatter and slag than MIG or TIG.

Related Article: Curious about the types of wires used in flux-cored and MIG welding? Read Common Welding Wires in MIG Welding and FCAW for a breakdown of wire types, classifications, and performance differences.

5. Submerged Arc Welding (SAW)

Why It’s Strong:

SAW delivers some of the strongest, cleanest, and most consistent welds possible, especially on large, heavy steel sections. The arc and molten pool are “submerged” beneath a layer of granular flux, protecting the weld from atmospheric contamination.

Because of their deep penetration and uniform heating, SAW joints exhibit exceptional tensile and fatigue strength.

Advantages:

- Deep fusion and smooth bead appearance.

- High deposition rates (up to 10 times faster than TIG).

- Minimal spatter and fumes.

Best For:

Pressure vessels, thick plates, pipelines, and heavy industrial projects.

Limitation:

Only suitable for horizontal or flat welding; not ideal for small projects or thin materials.

Weld Joint Designs That Maximize Strength

The welding process is only half the equation, joint design matters just as much.

1. Butt Joint

- Two metal pieces aligned edge to edge.

- Allows full penetration and strength equal to the base metal.

- Common in pipe and plate welding.

2. Groove Joint

- Uses a beveled edge to increase penetration.

- Ideal for thick materials requiring strong structural welds.

3. Fillet Joint

- Connects two surfaces at right angles.

- Used in T-joints, lap joints, and corner welds.

4. Plug or Slot Joint

- Used for overlapping sheets.

- Provides high shear strength in automotive and fabrication applications.

Pro Tip: Full-penetration groove welds are often the strongest because they fuse through the entire thickness of the material.

Factors That Weaken a Weld

Even if you use the right process, poor technique or setup can compromise strength. Avoid these common mistakes:

- Contamination: Dirt, oil, or rust on the base metal can cause porosity.

- Improper Heat Input: Too much heat causes distortion; too little prevents full fusion.

- Wrong Filler Metal: Always match filler metal to base material and strength requirements.

- Lack of Shielding Gas: Leads to oxidation and weak welds.

- Poor Joint Fit-Up: Gaps or misalignment reduce overall strength.

Testing Weld Strength

Professional fabricators often test welds to verify strength and reliability. Common methods include:

- Tensile Testing: Measures how much force the weld can withstand before breaking.

- Bend Testing: Evaluates ductility and fusion quality.

- X-Ray or Ultrasonic Testing: Detects internal defects or voids.

- Hardness Testing: Determines resistance to indentation or wear.

These tests ensure the weld meets industrial standards and safety regulations.

Tips for Stronger Welds

- Clean and prepare surfaces thoroughly.

- Match filler rods and base metals correctly.

- Use TIG welding rods or appropriate consumables for your method.

- Maintain a consistent torch angle and travel speed.

- Invest in professional welding machines from reputable brands like Yeswelder for performance and reliability.

Final Thoughts

The strongest weld isn’t just about the process — it’s about precision, preparation, and the right tools.

Whether you prefer TIG welders for clean, aesthetic work or MIG machines for high productivity, your results depend on quality equipment and solid technique.

Partnering with a trusted welding equipment supplier gives you access to certified machines, consumables, and accessories that guarantee consistent strength and durability.

In the end, the strongest weld is one that fuses science, skill, and craftsmanship — a bond built to last.

FAQ Section for What Is the Strongest Weld and How to Achieve It

TIG welding (GTAW) produces the cleanest and most precise welds. It uses a non-consumable tungsten electrode and shielding gas, which eliminates spatter and oxidation. This makes it the preferred choice for projects requiring smooth, visually perfect welds—especially in aerospace, stainless steel fabrication, and automotive applications.

MIG welding (GMAW) can be nearly as strong as TIG welding when done correctly, especially on thicker materials and structural applications. While TIG welds are cleaner and more precise, MIG welds offer higher productivity and deeper penetration, making them suitable for manufacturing and construction.

–TIG Welding (GTAW): Highest precision and cleanest welds, ideal for thin metals and critical joints.

–MIG Welding (GMAW): Deep penetration and high productivity, perfect for structural work.

–Stick Welding (SMAW): Extremely durable and reliable outdoors, excellent for heavy steel and construction.

Each method has its strengths—the strongest depends on the project type and material thickness