Choosing a MIG welder for stainless steel isn’t about buying the most expensive machine or the one with the highest power.

The key is selecting a welder that matches stainless steel’s needs—stable amperage, smooth wire feeding, proper gas compatibility, and the right output range.

Stainless steel reacts easily to heat, distortion, and discoloration, so not every welder can handle it well.

A MIG welder is often the best option because it offers good heat control, clean results, and a steady welding process.

Whether you’re a professional, a hobbyist, or someone who regularly works with stainless steel, understanding how a MIG welder operates is essential before purchasing one.

What is MIG Welders?

A MIG welder uses a continuous wire feed and shielding gas to create a clean, strong weld. The gas—usually a mix of argon and CO₂—protects the weld from contamination.

MIG welders are known for being easy to learn and operate, making them suitable for both beginners and experienced welders.

Core Features

- It features a continuous wire feed that smoothly and consistently feeds wire.

- It provides protection against atmospheric contamination using argon-rich mixtures.

- It offers full control over voltage and amperage tuning and adjustment.

- It provides ease of use for beginners, seasonal users, and professionals.

- It provides high compatibility for materials like steel, stainless steel, and aluminum

Why a MIG Welder for Stainless Steel?

The answer is that a MIG welder is fast, efficient, reliable, and the cleanest way to weld stainless steel. Because stainless steel is prone to heat, warping, and discoloration, it requires extra care during welding.

The MIG welder can handle this situation pretty well, as it offers better heat control and uses shielding gas to minimize the impact of atmospheric conditions. These features make it preferred by welders over TIG and Stick Welders.

Moreover, MIG welders are easy to handle and control. It features user-friendly operation and maintains a balanced welding process from start to finish. Similarly, when it comes to smooth finishing and less spatter, you will see MIG welders at the top.

Which MIG Welder Is best for Stainless Steel?

1: Miller Millermatic 211

The notable feature of Miller Millermatic 211 is its Auto-Set functionality, which automatically tunes the recommended settings based on the wire size and input material.

Other than that, it delivers stable, efficient, and clean welding on stainless steel and aluminum at 110/120V and 220/240V. Just make sure to use shielding gas ratios of 98/2 Ar/CO2, or as required.

Pros:

- Dual Voltage support.

- Works well for both low- and high-level welding tasks.

- Auto-Tuned adjustments to minimize the risk factors.

- Portability & Flexibility

- Brand Reputation

Cons:

- Expensive or Premium Price

- Accessories charge a separate Cost.

Best For: Hobbyists and Small Shop Professionals.

2: Lincoln Power MIG 210 MP

The Lincoln Power MIG 210 MP is a lightweight and portable welding machine. If we talk about a notable attribute, it allows switching between all TIG Welder and Stick Welder variants based on requirements.

It offers dual voltage at 120 V or 230 V, can be carried easily as it weighs only 18kg, and is able to deal effectively with mild stainless steel up to 8 mm.

Pros:

- Multi-Process Capability

- Portability and Flexibility

- Brand’s Strong Customer Support

Cons:

- More expensive than a single-process welder

- Limited Thickness Capability

Best For: Technicians and Small Shops

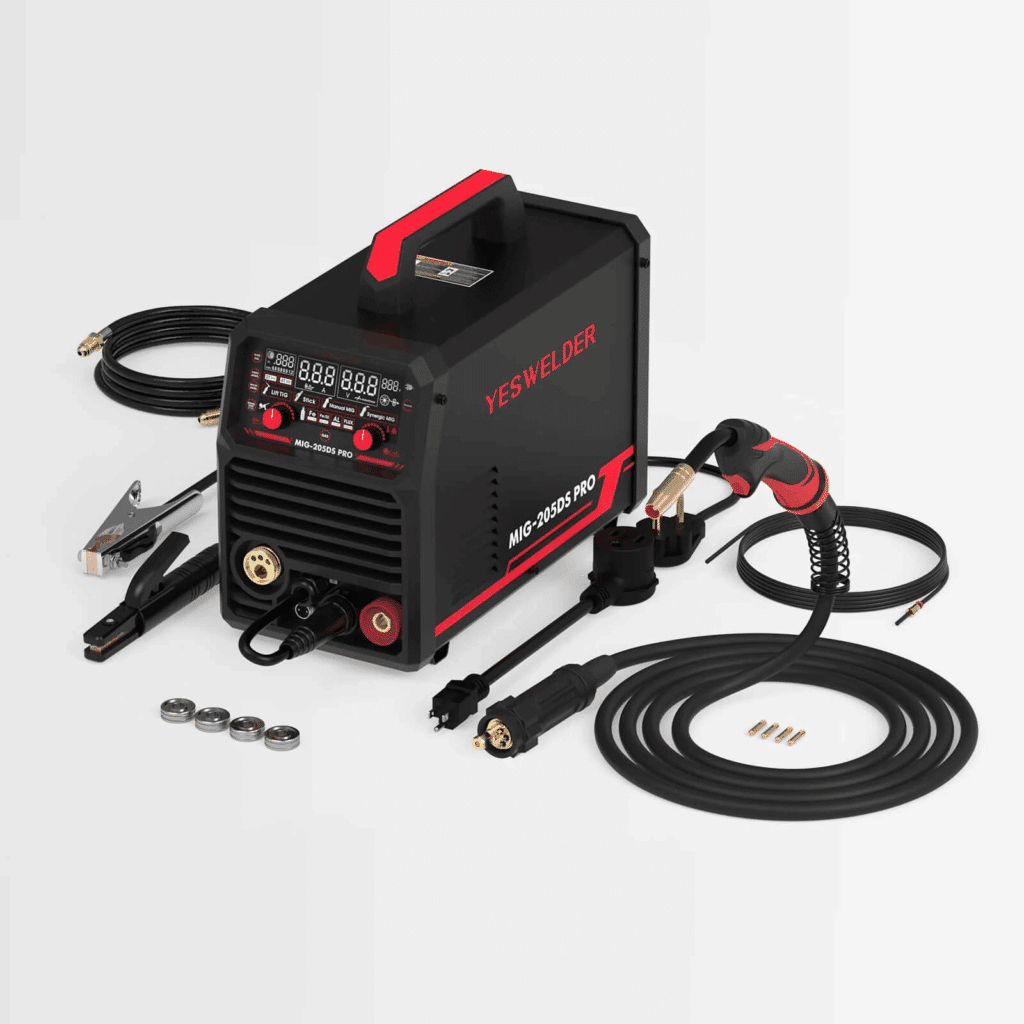

3: YesWelder MIG-205DS

The YesWelder MIG-205DS can switch between MIG, TIG, and Stick modes, yet it remains more affordable than many welders in its class.

It also offers dual-voltage capability, a digital display, and a portable design.

This makes it a solid choice for light to medium stainless steel work.

Pros:

- Best Price to Performance Ratio

- Multi-Mode Operation

- Dual Voltage Support

Cons:

- Limited Duty Cycle

Best For: Hobbyists and Budget Controlled Users

4: Hobart Handler 210 MVP

The Hobart Handler 210 MVP is an entry-level, best-for-beginners welding machine. The credit goes to its simple controls and less complexity.

The Handler 210 MVP features dual-voltage support, a rugged build, and the ability to weld 9.5 mm stainless steel. One can simply prefer these MIG welding machines for low to medium-level welding tasks.

Pros:

- Dual Voltage Support

- Good Thickness Capability

- Brand’s Customer Support

Cons:

- Heavy in Weight

Best For: New Welders, DIYers, and Small Shop Owners

5: Everlast Power i-MIG 200

The notable features of the Everlast Power i-MIG 200 include its good duty cycle and support for spool guns. i-MIG 200 is well-suited for light to moderate stainless steel welding, which, in return, proves efficient and cost-effective.

Similarly, it supports dual voltages, features a digital display, and feeds both 4″ and 8″ spools.

Pros:

- Decent Duty Cycle

- Budget Friendly

- Digital Display

- Dual Voltage

Cons:

- Pricy Everlast Guns

Best For: Semi-Professional Shops and Hobbyists requiring more Power.

Which Key Parameters Should You Consider ?

Before buying a MIG welder for stainless steel, it is mandatory to understand the requirements for basic parameters. Let’s check these,

- Dual Voltage: For lower tasks, use 120V, and for heavy tasks, use 240V.

- Output & Duty Cycle: Welding the stainless steel requires balanced amperage and travel speeds. Make sure to choose the one with enough duty cycles to avoid overheating.

- Wire Feed Mechanism: It ensures clean welding with no risk of birdnesting and burnback.

- Transfer Modes: Review the transfer modes—Short-Circuit, Pulsed, and Spray—to determine requirements for thick or thin materials.

- Gas Compatibility: The MIG welder you choose must be compatible with Argon Rich Mixtures to avoid atmospheric contamination.

- Build Quality & Service: Must receive prompt customer support from the manufacturer or seller.

Tips for Choosing the Best MIG Welder

- Use the correct filler wire: ER308L for 304 stainless and ER316L for 316 stainless.

- Pick a MIG welder with a high duty cycle so it can run longer without overheating.

- Make sure the machine supports argon-rich shielding gas, which is required for stainless steel.

- Consider portability if you plan to move the machine around your shop or job sites.

- Check the brand’s reputation, customer service, and spare-parts availability before buying.

Final Remarks

MIG welders remain one of the most practical tools for stainless steel because they offer controlled heat input and consistent results. Several models consistently perform well in this category.

The Miller Millermatic 211 provides excellent arc stability and a broad output range, making it suitable for a wide range of stainless jobs. The Lincoln Power MIG 210 MP stands out for its portability and multi-process flexibility.

If budget is a priority, the YesWelder MIG-205DS offers one of the strongest price-to-performance ratios while still supporting MIG, TIG, and Stick modes.

Related Articles

1. How to Weld Stainless Steel

2. Welding Stainless Steel vs Carbon Steel: What You Need to Know

3. MIG Welder Troubleshooting: 20 Common Problems & Quick Fixes